2 GYRATORY CRUSHERS 911 Metallurgist

The crusher frames or shells of large gyratory crushers are made of cast steel The original crushers used cast iron frames, a few of which are still used in the smaller crusher sizes These frames are made in two or more shells depending on the size of the crusher Available transportation clearances determine the max The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame Gyratory Crushers 911 MetallurgistGyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory Crusher an overview ScienceDirect Topics

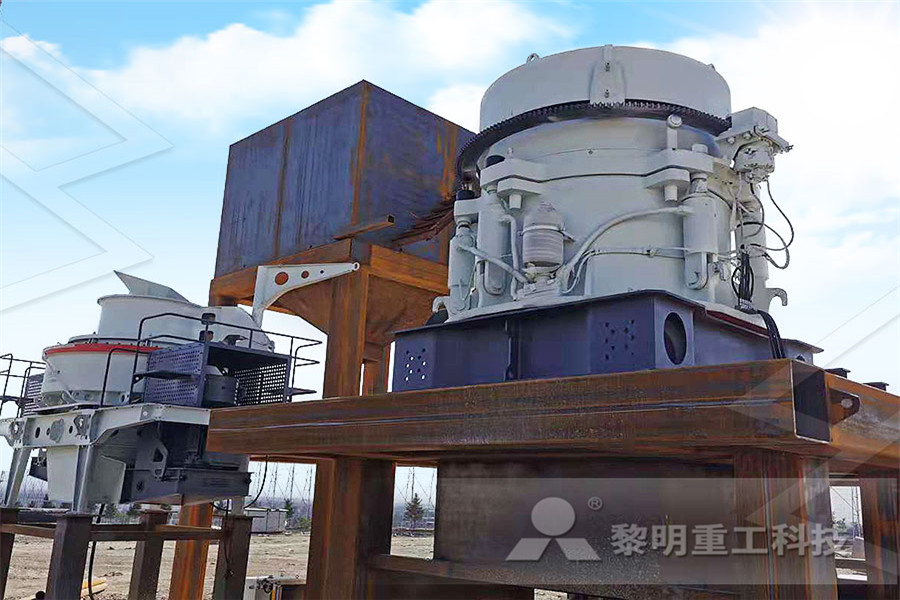

Technology Advanced LargeScale GC Gyratory

NMS GC5065 Gyratory Crusher The GC series gyratory crusher of NMS adopts advanced technology, such as large processing capacity, high crushing efficiency, large crushing ratio, uniform product size, low energy consumption, and uniform wear in the crushing cavity, comparing with other primary crushing equipment Gyratory Crusher Circuit Design In practice, large primary gyratory crushers are seldom installed underground They are invariably installed at the surface The charge is preferably fed directly off trucks, tipwagons, side dump rail cars and conveyor belts onto a receiving hopper, which feed the crusher through a chuteGyratory and Cone Crusher ScienceDirect The bevel gear and pinion of the crusher are both of a cyclopalloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of gyratory crusher Industrial Solutions Gyratory crushers

Gyratory Crushers SolidsWiki

A Gyratory Crusheris a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardness A Gyratory Cone Crusheris one of the main types of primary crushers in a mine or ore processing plant A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust There are five types of crushers; Jaw crusher, Gyratory crusher, Cone crusher, Impact crusher and Mineral sizers A gyratory 4265 Gyratory Crusher Engineering Channel Gyratory Crushers Gyratory crusher is generally used as a primary crusher The crusher is popular due to its high throughput capacity and the large sized opening The crusher is well suited for handling direct feed from haul/dump trucks The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strengthConstruction, Working and Maintenance of Crushers for

The Advantages and Disadvantages of Gyratory

The basis weight of gyratory crusher machine is usually 23 times of the weight of the main part, and the basis weight of jaw crusher machine is 510 times the weight of the machine itself; 3 It can be packed to the mine, and large gyratory crusher can SMX Series Gyratory crusher is a largescale crushing machine used for primary crushing of various hard ores or rocks, the feed material will be compressed, broken and bended through gyrating movement of breaking head within the chamber Capacity 11206813t/h Max feeding sizeSMX Series Gyratory Crusher SHANGHAI SANME New largecapacity primary crusher for above and underground applications 22012021 Outotec has launched an extension to it’s primary gyratory crusher range: The SUPERIOR™ MKIII 6275UG The new crusher, which can be used in different types of applications, provides large capacity with significant savings in CAPEX and operating costs New largecapacity primary crusher for above and

Gyratory Crusher (KG model)|Crushing/Grinding

Gyratory Crusher (KG model) FEATURES Simple Discharge Set Adjustment The discharge setting is adjusted by the amount of oil in the hydraulic cylinder installed at the bottom of the main shaft. Preventing the Main Shaft from Falling Down If a large hard ore Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC The Gyratory Crusher “NT” incorporates all of the TC’s heavyduty design features (Heavy CastSteel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, LongLife Bronze Components) and focuses on coupling these historical characteristics with updated maintenancefriendly featuresHeavy duty, maintenancefriendly Gyratory Crusher

Gyratory Crushers SolidsWiki

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley The basis weight of gyratory crusher machine is usually 23 times of the weight of the main part, and the basis weight of jaw crusher machine is 510 times the weight of the machine itself; 3 It can be packed to the mine, and large gyratory crusher can The Advantages and Disadvantages of Gyratory Fortescue to receive thyssenkrupp’s largest ever gyratory crusher at Iron Bridge which involves construction of a largescale process plant and port infrastructure for the site’s high Fortescue to receive thyssenkrupp's largest ever

Crushers QueensMineDesignWiki

Gyratory crushers generally cost less than $1500 per hour to run, while Jaw crushers cost less than $200, including electricity (Infomine, 2008) Rules of Thumb • A 42inch gyratory crusher produces approximately 24 tons per horsepowerhour (29 t/kWh)With the right Gyratory Crusher Wear Plates for your site and use case, you’ll find greater reliability in your equipment and you will keep productivity high Reduced OPEX Keep your machinery running longer and reduce operating expenditures with Gyratory Crusher Wear Parts made from the Gyratory Crusher Wear Plates New largecapacity primary crusher for above and underground applications 22012021 Outotec has launched an extension to it’s primary gyratory crusher range: The SUPERIOR™ MKIII 6275UG The new crusher, which can be used in different types of applications, provides large capacity with significant savings in CAPEX and operating costs New largecapacity primary crusher for above and

Gyratory Crusher (KG model)|Crushing/Grinding

Gyratory Crusher (KG model) FEATURES Simple Discharge Set Adjustment The discharge setting is adjusted by the amount of oil in the hydraulic cylinder installed at the bottom of the main shaft. Preventing the Main Shaft from Falling Down If a large hard ore This NMS gyratory crusher can meet all your requirements It has large capacity, low energy consumption, high crushing efficiency, high reduction ratio, high quality and reliable return on investment It is your best choice High capacity and energysavingSuper Capacity! NMS GC5065 Gyratory Crusher, You Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to Gyratory Crusher l Introduce, Working Principle JXSC

Gyratory and Cone Crusher ScienceDirect

Gyratory Crusher Circuit Design In practice, large primary gyratory crushers are seldom installed underground They are invariably installed at the surface The charge is preferably fed directly off trucks, tipwagons, side dump rail cars and conveyor belts onto a receiving hopper, which feed the crusher through a chuteThe Gyratory Crusher “NT” incorporates all of the TC’s heavyduty design features (Heavy CastSteel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, LongLife Bronze Components) and focuses on coupling these historical characteristics with updated maintenancefriendly featuresHeavy duty, maintenancefriendly Gyratory Crusher Each crusher’s capacity is 2,500 t/h, while the feeders operate at 2,500 t/h (speed: 025 m/s) says its TSU Gyratory Crusher is specifically designed for extreme applications, where extra motor power and heavier sections are needed and where reliability and to provide gyratory crushers and apron

Fortescue to receive thyssenkrupp's largest ever

Fortescue to receive thyssenkrupp’s largest ever gyratory crusher at Iron Bridge which involves construction of a largescale process plant and port infrastructure for the site’s high SP50 GYRATORY CRUSHER Increased capacity, with reduced maintenance and downtime is what the SP50 Secondary Gyratory Crusher delivers The SP50 features tramp iron relief via accumulator and relief valve, adjustable stroke, roller bearing eccentric mechanism, a spherical plain spider bearing, removable spider arm,SP50 GYRATORY CRUSHER With the right Gyratory Crusher Wear Plates for your site and use case, you’ll find greater reliability in your equipment and you will keep productivity high Reduced OPEX Keep your machinery running longer and reduce operating expenditures with Gyratory Crusher Wear Parts made from the Gyratory Crusher Wear Plates