mexico grinding ball wear rate mining

Modeling and prediction of wear rate of grinding media in Aug 03 2020 A data set derived from 50 experiments on the wear rate of a low alloy steel ball was applied in this work The experimental data were obtained from literature The experimental conditions influential factors and the total wear rate for each experiment which was determined by the grinding media weight loss are implied in Grinding Media Wear Rate Calculation in Ball Mill Grinding Media Wear Rate Calculation in Ball Mill thereby showing the accuracy of the formula and the truth of the law of ball wear At the Golden Cycle Mining and Reduction Co’s plant a dry crushing test was made on a 6 ft 2 in by 6ft (185 by 18m) w = weight of any ballGrinding Media Wear Rate Calculation in Ball Mill Powder Technology, 47 (1986) 87 96 Mathematical Model of Ball Wear in Grinding Mills 1 ZeroOrder Wear Rate J MENACHO Mining and Metallurgical Research Center, CIMM, Casilla 170, Correo 10, Santiago (Chile) and F CONCHA Department of Metallurgical Engineering, University of Concepcion, Casilla 53C, Concepcion (Chile) (Received November 6, 1985) 87 SUMMARY Using a Mathematical model of ball wear in grinding mills I

Grinding Media Balls for Mines and Minerals

There is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solutionAlibaba offers 25,196 grinding ball for mining products A wide variety of grinding ball for mining options are available to you, such as material, local service location, and applicable industriesgrinding ball for mining, grinding ball for mining Milling Equipment: Cement mill grinding media wear rate mining A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 mesh Get A QuoteCement Mill Grinding Media Wear Rate Binq Mining

Grinding Ball Wear Corrosion 911metallurgist

Two types of wear mechanisms were identified in grinding the CuNibearing sulfide gabbroic rock: (1) a straininduced corrosion mechanism associated with abrasive gouging was prevalent in softer grinding media such as mild steel while, (2) a pitting corrosion mechanism associated with segregated areas in the ball Shouding multiple rhombic grinding ball Φ60、Φ80、Φ100、Φ110、Φ120mm ¥ 560000 In Stock: 5000Grinding ballConsumablesMiningCircle A material's susceptibility to wear depends on its physical and mechanical properties as well as on environmental factors, ie, the conditions to which the material is exposed In other words, the wear is a function of the tribosystem (), which is made up of four elements: body, counterbody, interfacial element and environmentThe action of each one of these elements can vary, as well as the A discussion on the measurement of grinding media

Quality Grinding Steel Balls Grinding Media Balls

Cast iron and forged Grinding Steel balls , Dia 20140mm grinding media ball Forged Grinding Ball Chile Copper Mining Forged Grinding Ball High Hardness Grinding Media Balls dia 20150mm B2 material mining use Forged grinding steel ball Low breakage Forged Grinding Ball 20130mm 45# 60Mn B2 B3 Material forging steel ballsThere is no standard solution for mineral industry and wear rate of grinding media varies from mine to mine, ore to ore and even for the same ore time to time Different alloys are recommended depending on ore type and mill particulars in order to arrive at the most cost economic solutionGrinding Media Balls for Mines and Minerals ball mill wear rate Grinding Equipment Manufacturer determining the wear rate on balls in a ball mill abrasive and impactive wear of grinding balls in rotary mills saimm apr 4, 1986 related to the rate of ball wear by a consideration of the number of balls in a size interval, as follows if nj is the number of balls in the mill whose Read moreDetermining The Wear Rate On Balls In A Ball Mill

Wear Tests on Grinding Balls 911 Metallurgist

Wear Tests on Grinding Balls BY T E NORMAN,' JUNIOR MEMBER AIME AND C M LOEB, JR, MEMBER AIME (New York Meeting February 1948) THE use of ball, rod and tube mills for grinding ore, cement and other materials has grown so rapidly during the past forty years that the world's annual consumption Grinding Balls in alloy steel rolled and/or stamped We supply balls on a wide and complete range of hardnesses, with different hardness profiles, to maximize the grinding performance in wear rate and impact endurance, at a regular wear and with tailor Supplier mining grinding media mill steel forged balls Thus, this study sheds light on the cost of wear rate associated with ball mill at Mahd Ad Dahab Gold Mine, Saudi Arabia, and its significant impact on the efficiency of grinding operation Keywords: grinding process, wet and dry grinding media, wear, ball mill, Mahd Ad Dahab Mine 1 INTRODUCTION Comminution is an indispensable process of mineralMining of Mineral Deposits pdfs

Grinding ballConsumablesMiningCircle

Shouding multiple rhombic grinding ball Φ60、Φ80、Φ100、Φ110、Φ120mm ¥ 560000 In Stock: 71 A material's susceptibility to wear depends on its physical and mechanical properties as well as on environmental factors, ie, the conditions to which the material is exposed In other words, the wear is a function of the tribosystem (), which is made up of four elements: body, counterbody, interfacial element and environmentThe action of each one of these elements can vary, as well as the A discussion on the measurement of grinding media Ball mills are common grinding equipment in mineral processing industries Ball wear results from three mechanisms namely impact, abrasion and corrosion Of these, the corrosion mechanism is the least investigated, due to its chemicalelectrochemical nature Therefore, the aims of this research were to investigate the grinding chemistry influence (slurry pH, solid percentage, water chemistry An investigation of the corrosive wear of steel balls in

Investigating the controllable factors influencing the

In determining the ball mass losses through total wear, 15 steel balls were handpicked and marked and then before and after each grinding experiment were weighted to calculate the ball losses Then, the wear rate in mils penetration per year (mpy) was Liner wear is still an issue as it relates directly to costs and bowl and mantle changeout times of 24 hours are still common Cone crushers dominate the hard rock crushing market; however, other The Evolution of Crushing and Grinding In ball mill operaton, especially in wet, wear of ball is not only a significant item of grinding expense, but an important factor affecting grinding performance Seasoned ball load performs actual grinding work, and its properties are formed by wear and renewal of ball Weight and size distribution are main properties of ball load related to Grinding Ball Wear and Ball Mill Operation Control

Effects of percent solids and mill loading on ball wear

The effects of percent solids, mill loading, and grinding time on product size distribution and ball wear were studied in a laboratory ball mill for a taconite ore Mild steel balls and HCLA steel balls were used to examine the role that ball hardness play in grinding Net production of −44µm (−325mesh) material reached maximum at 70% solids, whereas the ball wear decreased as pulp Milling Equipment: Cement mill grinding media wear rate mining A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 mesh Get A QuoteCement Mill Grinding Media Wear Rate Binq Mining 3 Control the filling rate of steel ball When the rotation speed of the ball mill machine reaches a certain degree, the filling rate is large, and the impacting times of steel ball on the material are more, the grinding area is large and the wear is fastHow to Reduce the Wear of Steel Ball in the Ball Mill

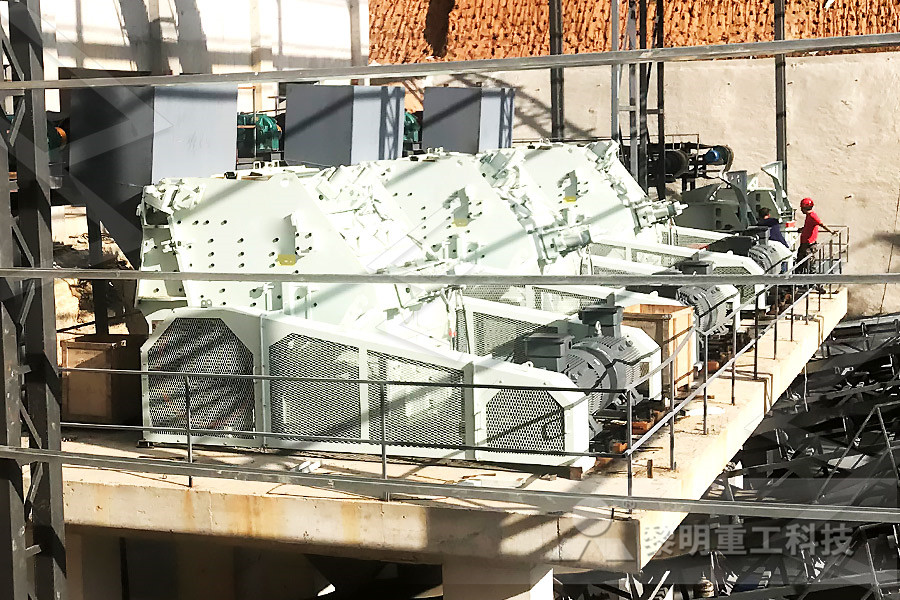

Supplier mining grinding media mill steel forged balls

Grinding Balls in alloy steel rolled and/or stamped We supply balls on a wide and complete range of hardnesses, with different hardness profiles, to maximize the grinding performance in wear rate and impact endurance, at a regular wear and with tailor Forged Grinding Ball Application: Mining, Cement plant, Power plant, Chemical Industry Product features: Breakage rate is lower than 05%,breakage resistance is better than casting ball Impact stress is more than 12J/c m’, Dropping test in 8m high tester for more than 20,000 times, Surface hardness 5865HRC , core hardness 5663HRC , Volumetric hardness 5764HRCGrinding Media Natus Online Distributing of Ball mills are common grinding equipment in mineral processing industries Ball wear results from three mechanisms namely impact, abrasion and corrosion Of these, the corrosion mechanism is the least investigated, due to its chemicalelectrochemical nature Therefore, the aims of this research were to investigate the grinding chemistry influence (slurry pH, solid percentage, water chemistry An investigation of the corrosive wear of steel balls in

Effect of martensite and austenite on grinding media

Wear, 14 (1969)445 7 D E Diesburg and F Borik, Optimizing abrasion resistance and toughness in steels and irons for the mining industry, Symp on Materials for the Mining Industry, Vail, CO, July 1974, p15 299 8 J C Farge and G A Barclay, Properties and performance of cast iron grinding balls, Symp on Materials for the Mining Grinding steels and metals (3) Mining, surface machinery and equipment (3) Precision balls (3) good wear resistance, low rate of breakage according to different demands of the ore hardness and mining Supplier of: grinding balls Forged Grinding Ball is made from steel, heated by energyefficient industion bar heating furnace suppliers grinding balls purchase quote Europages The medium filling rate is the volume ratio of the medium and grinding cavity, moves in throwing and falling state in a ball mill The throwing motion medium is used to smash large ore, and the medium of falling movement mainly plays the role of grinding The filling rate of the fine grinding mill is about 5% lower than that of the coarse grindingFactors Influence Ore Grinding Mill Efficiency JXSC