working principal of raw mill netwerkoostkampbe

working principle of raw mill in cement plant Working principle of raw mill in cement plant a cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical roller mills the cement Get priceraw mill working principle As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone raw mill working principle homecucineplWorking Principal Of Vartical Raw Mill OK™ Mill working principle by FL YouTube 50+ videos Play all Mix OK™ Mill working principle by FL YouTube KMC CMP AVI 05 Vertical Roller Mill Duration: 12:46 Versatylo Interactive 9,851 views suijitupian89jpg" /> Hammer Mill: components, operating principles, Hammer mill is the most widely used grinding mill and amongWorking Principal Of Vartical Raw Mill 2

working principal of vartical raw mill in zimbabwe

working principal of vartical raw mill in zimbabwe Vertical Roller Mill Structure And Working Principle,WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time hot air comes into the mill from the air inlet Due to the centrifugal force raw mill working principle castell montgri nl Working principle of cement plant raw mill,raw material mill working principle raw mill usually uses the edge transmission mode, and the raw material mill uses rim drive, after the materials having continuously and uniformly sent to the internal raw material mill by the feeding machines, the electric motor drives the mill cylinder rotary motion working principle of raw mill in cement plantWorking Principal Of Vartical Raw Mill Turkey Formula for table output rpm of vertical raw mill formula for table output rpm of vertical raw mill vertical raw mill Crusher Greywacke Vertical with CLASSIFIER Critical pace of vertical mill bowl mill working animationrelated information, including This raw soakedoat cereal takes Anson MillsFurther, our vertical roller mill solution for Working Of Vertical Raw Mill temrajcz

Raw mills for all requirements Gebr Pfeiffer

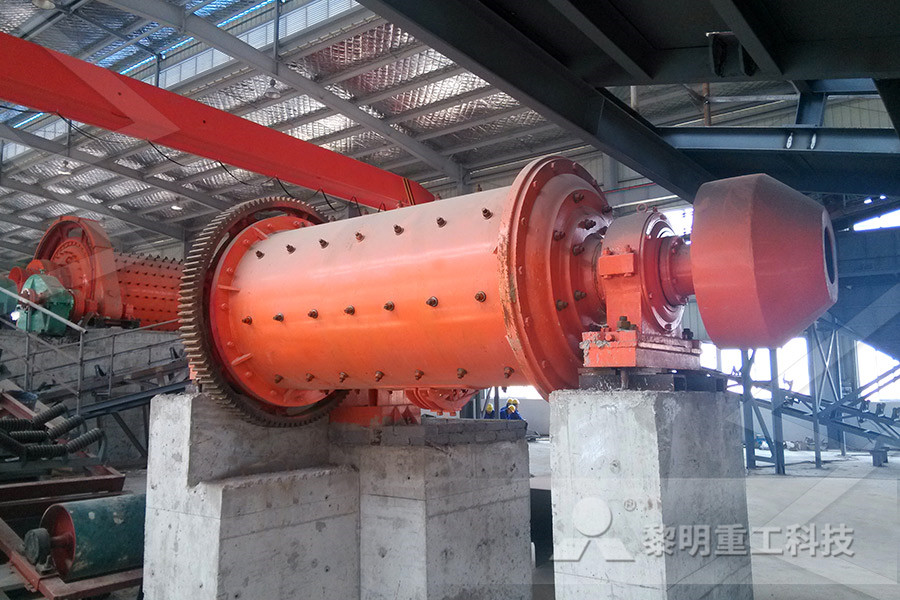

Depending on its deposit and composition, the cement raw material may contain a more or less big portion of water Especially with high feed moistures, drying is of particular importance because the existing surface moisture has to be evaporated almost down to zero in the raw mill Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Working Principle And Main PartsNo matter what type of material has to be ground – cement raw material, cement clinker or granulated blastfurnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a different dimension, around the Cement mills and raw mills for high throughput rates

raw mill working principle homecucinepl

raw mill working principle As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls Then, discharge of ground material performed The operating principle of the ball mill Primo PizzaNo matter what type of material has to be ground – cement raw material, cement clinker or granulated blastfurnace slag – and how different their grindability and abrasiveness may be, the MVR mill ensures throughput rates of a different dimension, around the clock, reliably and on Cement mills and raw mills for high throughput rates

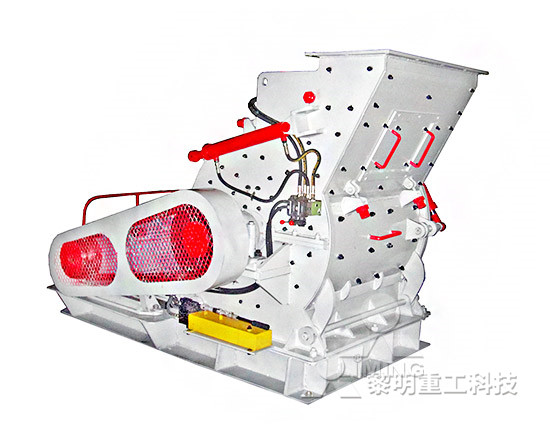

Hammer Mill: components, operating principles, types, uses

Their working and grinding actions remain similar despite the fact that their construction differs in many respects Pharmaceutical uses of Hammer Mill 1 It is used in pharmaceutical industries to process wet or dry granulations and disperse powder mixtures 2 It is used in milling pharmaceutical raw materials, herbal medicine, and sugar Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granules It consists of two horizontal steel plates with vertical projections arranged in concentric circles on opposing faces and becomes more closely spaced towards the periphery Pin millPin Mill: Description, operating principles, advantages A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell The nanostructure size can be varied by varying the number and size of Ball Mills an overview ScienceDirect Topics

Principle of operation bowl mill SlideShare

Principle of operation bowl mill 1 Principle of Operation Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft The worm shaft drives worm gear, mounted on the Main Vertical Shaft A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpm A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine is similar to all type of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge pointThe motion is, however, a more complex one than the Dodge motion, being the Jaw Crusher Working Principle 911 Metallurgist A tablet coating machine is an equipment that coats the external surface of a tablet using a thin film of coating material Working principle of tablet coating machine is relatively simple where the application of coating material is done on a moving bed of tablets and removing rapidly the solvent using a current of hot airWorking and Principle of Tablet Coating Machine

Vibrating Screen Types Working Principle [How To Choose

The working surface of the roller screen is composed of a series of rolling shafts that arranged horizontally, on which there are many screen plates When working, the fine material passes through the gap between the roller or screen plate, large blocks of materials are driven by rollers, moving to the ends and discharging from the outlets Pin mill is a kind of milling equipment that can break up cellular materials selectively without damaging the starch granules It consists of two horizontal steel plates with vertical projections arranged in concentric circles on opposing faces and becomes more closely spaced towards the periphery Pin millPin Mill: Description, operating principles, advantages Their working and grinding actions remain similar despite the fact that their construction differs in many respects Pharmaceutical uses of Hammer Mill 1 It is used in pharmaceutical industries to process wet or dry granulations and disperse powder mixtures 2 It is used in milling pharmaceutical raw materials, herbal medicine, and sugarHammer Mill: components, operating principles,

Ball Mills an overview ScienceDirect Topics

A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shell The nanostructure size can be varied by varying the number and size of Principle of operation bowl mill 1 Principle of Operation Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft The worm shaft drives worm gear, mounted on the Main Vertical Shaft A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpmPrinciple of operation bowl mill SlideShare The mill also includes the processes of attrition and impact, although these actions are limited if the material is easily reduced by cutting and the screen limiting discharge has large perforations The mill consists of a rotating shaft with four attached parallel knives and a screen occupying one fourth of the 360 degree rotationChapter 18 Feed Milling Processes FAO

The Pulp and Paper Making Processes Princeton

THE PULP AND PAPER MILL Although there are several chemical and mechanical pulping methods used for delignifying wood (table 2l), separating fibers, and removing discoloration, all integrated pulp and paper mills involve the same general steps in the manufacture of pulp and paper These steps include: 1 ) raw material A tablet coating machine is an equipment that coats the external surface of a tablet using a thin film of coating material Working principle of tablet coating machine is relatively simple where the application of coating material is done on a moving bed of tablets and removing rapidly the solvent using a current of hot airWorking and Principle of Tablet Coating Machine The biogas formed from a digester is comprised primarily of methane, carbon dioxide, and other trace gases A biogas plant generates biogas from organic substances such as cattle –dung, and other biodegradable materials such as biomass from farms, gardens, kitchens and night soil wastes, etc The process of biogas generation is known as anaerobic digestion (AD)Biogas Production Process, Working Principles, Plant

Vibrating Screen Types Working Principle [How To

The working surface of the roller screen is composed of a series of rolling shafts that arranged horizontally, on which there are many screen plates When working, the fine material passes through the gap between the roller or screen plate, large blocks of materials are driven by rollers, moving to the ends and discharging from the outletsElectron Hole Formation As we know that photon is a flux of light particles and photovoltaic energy conversion relies on the number of photons striking the earth On a clear day, about 44 x 10 17 photons strike a square centimeter of the Earth’s surface every second Only some of these photons that are having energy in excess of the band gap are convertible to electricity by the solar cellSolar Cell Construction Working Principle –