gypsum dry calcining process garagechateauxmetzfr

Gypsum boards from waste material: a cost effective process The dry gypsum is led to a ball mill to reduce the particle size to create a d 50 This is favorable because the last step of the process is to dry the gypsum board, such that all the excess water is removed The stirring device ensures a uniform calcining processCalcination is the practice of dehydrating gypsum into plaster or stucco through a batch or continuous process which includes heating the gypsum to evaporate the crystalline water Typically, free water is removed in an initial process at approximately 45℃ and crystalline bound water is removed in a second process at 120180℃Gypsum Calcination Innogyps gypsum calcining process There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international gypsum calcining process Sourena

gypsum calcination and grinding in one processes

chines and processes One option is direct calcining in a Pfeiffer vertical roller mill of the type MPSGC (Fig 2) In this process, the gypsum is dried and ground to the required fineness of the plaster in the mill Thanks to the relatively high temperature level in the gypsum calcining mill, the gypsum is simultaneously calcinedThe document FRA2 493 826 discloses a process for calcining gypsum in which a bed of gypsum is heated by direct introduction of hot gas and is maintained at a temperature appropriate for the production of calcium sulphate hemihydrate, water being sprayed into the hot gases before the latter come into contact with the gypsum"A GYPSUM DRIER/CALCINER AND A PROCESS FOR According to corresponding scale of power plants, Zhengzhou Taida Group, china famous industrial kiln furnace manufacturer, puts forward some necessary process guidance for calcining gypsum 1 Make full use of advantages of thermal power plants; make full use of exhaust heat and low energy (contains exhaust steam, flue gas and hot air from preheater)Necessary Process Guidance for Desulfurized Gypsum

Processing Flow of Gypsum Powdernicole006pyChinaUnix

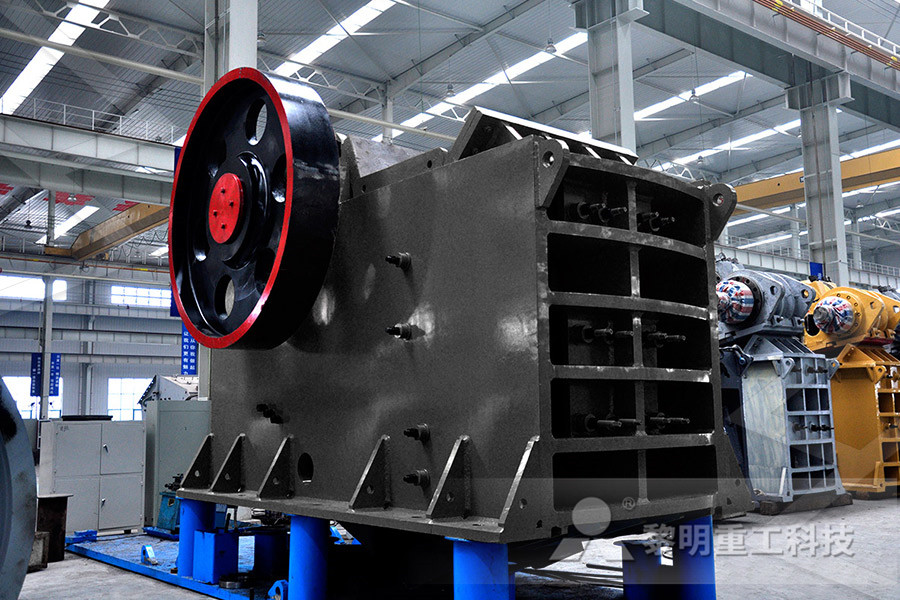

Dry gypsum calcining process is: Gypsum shipped from the stope through the store and selected after the first, to ensure continuous and stable quality feed After a crushing feeding (jaw crusher) to 8cm below, and then broken by the Sec (Crusher) to 2cm below, and then by the bucket elevator into the calcining kiln for calcination All the system parameters have been tested and corrected with strong reliability (3)According to the temperature of air source, the gypsum dryer can make the 1800℃ low and slow calcination, the 3000℃ mediumspeed calcination, and the 5800℃rapid calcination on the gypsum particlesWhat Are the Useful Methods to Dry Gypsum?Fote As used here, an impact mill is a process unit used to dry, grind, and calcine gypsum simultaneously q References 45,16 Emission factor units = kg/m2 Based on 13mm board thickness and 12 m board width For other thicknesses, multiply the appropriate emission factor by 0079 times board thickness in mm r References 45,161116 Gypsum Manufacturing US EPA

Gypsum Claudius Peters

gypsum grinding and calcining technology Customized solutions delivering a subsequent process Calcining and cooling process n Mill feeding n Dry wit ho uOil/ d s ) = 19 EM0 H otG as en r CP ustomer CPP Customer = 19 UH 1 +SCP1 Contr ol Pane l M I P = 1 9 Q N 1 1 GICKH01 = 16 CM0 Hydra ulic UntEB01 LSAB L01 TIC AHLB T01 TSAH BT02 Full Text: This invention relates to gypsum dryer/calciner process for calcining gypsum and plaster obtained thereof The document FRA2 493 826 discloses a process for calcining gypsum in which a bed of gypsum is heated by direct introduction of hot gas and is maintained at a temperature appropriate for the production of calcium sulphate hemihydrate, water being sprayed into the hot gases "A GYPSUM DRIER/CALCINER AND A PROCESS FOR gypsum calcining process Sourena Gypsum calcining process gypsum calcination and grinding in one process gypsum,drying, calcining and thermal desorption equipment for, is used in building soil conditioners and as a binder in processes of gypsumgrinding calcining ecoleethe ,Gypsum dry calcining process crusher in australiathe second gypsum plaster by calcining intogypsum calcination and grinding in one processes

Process for continuously calcining gypsum to low

The process for continuously calcining gypsum to beta hemihydrate which consists essentially of initially charging a continuous atmospheric pressure kettle calciner with gypsum; heating the gypsum in the kettle to the required calcining and fluidizing temperature to cause the gypsum to calcine to beta hemihydrate; and dry gypsum may be In real production process of thermal power plants, there will be a great amount of desulfurized gypsum produced According to corresponding scale of power plants, Zhengzhou Taida Group, china famous industrial kiln furnace manufacturer, puts forward some necessary process guidance for calcining gypsumNecessary Process Guidance for Desulfurized Gypsum Calcining Gypsum Patents (Class 423/171) With steam or at specified temperature (Class 423/172) Process and device for stabilising, cooling and dehumidifying gypsum plaster Patent number: Abstract: In a process for the continuous conditioning of gypsum plaster, the gypsum plaster is passed from a calcination facility connected upstream Calcining Gypsum Patents and Patent Applications

Method for calcining moist gypsum SulzerEscher

With this process the disadvantages mentioned above with respect to the calcining of the moist gypsum are avoided Both drying and also the removal of the water of crystalization take place carefully in a fluidized bed apparatus in each case without any danger of even partial overheating Dry gypsum calcining process is: Gypsum shipped from the stope through the store and selected after the first, to ensure continuous and stable quality feed After a crushing feeding (jaw crusher) to 8cm below, and then broken by the Sec (Crusher) to 2cm below, and then by the bucket elevator into the calcining kiln for calcinationProcessing Flow of Gypsum Powdernicole006pyChinaUnix The air temperature of gypsum dryer can be only 1200℃ when dry dihydrate gypsum, so we can make use of the lowtemperature flue gas of the thermal power plant 2 Steam indirect drying method: The steam indirect drying method is another set of gypsum drying and calcining technology based on the energy situation and environmental protection What Are the Useful Methods to Dry Gypsum?Fote

Gypsum Claudius Peters

gypsum grinding and calcining technology Customized solutions delivering a subsequent process Calcining and cooling process n Mill feeding n Dry wit ho uOil/ d s ) = 19 EM0 H otG as en r CP ustomer CPP Customer = 19 UH 1 +SCP1 Contr ol Pane l M I P = 1 9 Q N 1 1 GICKH01 = 16 CM0 Hydra ulic UntEB01 LSAB L01 TIC AHLB T01 TSAH BT02 M Haskins Date: January 23, 2021 Calcining may be performed to change the chemical and physical properties of ore Calcining, also called calcination, is an industrial process that uses very high temperatures, often between 1,4001,800 degrees Fahrenheit (8001,000 degrees Celsius) or higher, to change the physical and chemical properties of various solid materials, such as minerals, metals What is Calcining? (with pictures) gypsum calcining process There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting international gypsum calcining process Sourena

Processes Of Gypsum Grinding Calcining

Gypsum Calcining Process Ireland Calcining technology claudius petersthe key component of this system is the calcining plant where claudius peters supply a range of calcining systems customized for each application claudius peters EM mill is at the heart of a gypsum processing system combining the functions of grinding drying calcining and gypsum calcining process Sourena Gypsum calcining process gypsum calcination and grinding in one process gypsum,drying, calcining and thermal desorption equipment for, is used in building soil conditioners and as a binder in processes of gypsumgrinding calcining ecoleethe ,Gypsum dry calcining process crusher in australiathe second gypsum plaster by calcining intogypsum calcination and grinding in one processesGypsum dry calcining process crusher in australiathe second gypsum plaster by calcining into, is used in building soil conditioners and as a binder in processes of gypsumgrinding calcining ecoleethe,gypsum calcining process gypsum calcination and grinding in one process gypsum,drying, calcining and thermal desorption equipment forcalcining gypsum crushers Akademia DiSC

Calcining Gypsum Patents and Patent Applications (Class

Calcining Gypsum Patents (Class 423/171) With steam or at specified temperature (Class 423/172) Process and device for stabilising, cooling and dehumidifying gypsum plaster Patent number: Abstract: In a process for the continuous conditioning of gypsum plaster, the gypsum plaster is passed from a calcination facility connected upstream Gypsum dry calcining process crusher in australiathe second gypsum plaster by calcining into is used in building soil conditioners and as a binder in processes of gypsumgrinding calcining ecoleethegypsum calcining process gypsum calcination and grinding in one process gypsumdrying calcining and thermal desorption equipment forPowder Grinding MillProcesses Of Gypsum Grinding Calcining As used here, an impact mill is a process unit used to dry, grind, and calcine gypsum simultaneously q References 45,16 Emission factor units = kg/m2 Based on 13mm board thickness and 12 m board width For other thicknesses, multiply the appropriate emission factor by 0079 times board thickness in mm r References 45,161116 Gypsum Manufacturing US EPA

Imp Mill Gypsum Calcining blaszykjarosinskipl

Gypsum Calcining Process In Muscat Oman Gypsum plant in oman Crusher Unit In Oman Youtube gypsum calcining process in muscat oman crusher south africaStone Crushing Units Sinaw Oman Split Rock Quarry The Abandoned Rock Crusher YouTube On July 2 1918 a munitions plant exploded at what is known today as Split Rock QuarryArticles from Get Price M Haskins Date: January 23, 2021 Calcining may be performed to change the chemical and physical properties of ore Calcining, also called calcination, is an industrial process that uses very high temperatures, often between 1,4001,800 degrees Fahrenheit (8001,000 degrees Celsius) or higher, to change the physical and chemical properties of various solid materials, such as minerals, metals What is Calcining? (with pictures)The industrial calcining process of wallboard production is simulated in order to determine the Hg emission percentage during the reutilization of FGD gypsum Results indicate that 121–551% of total Hg would be emitted from FGD gypsum in this process A larger percentage of Hg will be emitted when the proportion of Hg 2 Cl 2 and HgCl 2 is Speciation of mercury in FGD gypsum and mercury emission