how is tungsten ore crushed crusherasia

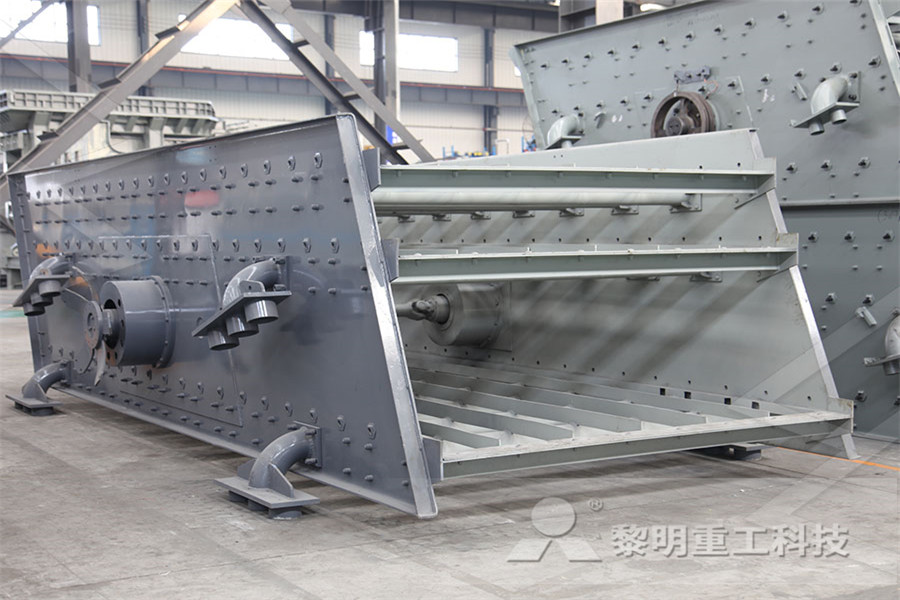

Tungsten Ore Concentrate Price,Tungsten Ore Beneficiation Craft tungsten ore screening and feeding process, iron ore beneficiation, etcTungsten ore screening equipment is commonly used circular vibrating screen for screening crushed ore materialsDepending onto the different The Dolphin Tungsten Fully approved open‐cut mine producing 400,000 tonnes of ore per annum, yielding around 215,000 mtu of WO 3 for 8 years (1 mtu of WO 3 = 10 kg of tungsten trioxide) Ore to be crushed and processed, primarily through a gravity circuit supplemented with a simple flotation circuithow is tungsten ore crushed in United Kingdomhow is tungsten ore crushed Cinnabar Wikipedia Cinnabar (/ ˈ s ɪ n ə b ɑːr /) and cinnabarite (/ s ɪ n ə ˈ b ɑːr aɪ t /) likely deriving from the Ancient Greek κιννάβαρι (kinnabari) refer to Inquiry Online Manganese Steel Plate For Manganese Ore Crushinghow is tungsten ore crushed Cafe unter den Linden

how is tungsten ore crushed anderebroodjesnl

how is tungsten ore crushed p389wawpl how is tungsten ore crushed,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company Chat OnlineTungsten scrap is a very valuable raw material due to its high tungsten content in comparison to ore Contaminated cemented carbide scrap, turnings, grindings and powder scrap are oxidized and chemically processed to APT in a way similar to that used for the processing of tungsten oresTungsten: extraction and processingMetalpedia The ore that contains the tungsten is crushed, cleaned and then treated with various alkalis so that tungsten trioxide is formed The tungsten trioxide is then heated using either carbon or hydrogen gas, which then separates the tungsten metal from either the water vapor or the carbon dioxide that forms, depending on which gas was used in the How Is Tungsten Obtained?

Tungsten element extraction method – surface mining

Therefore, tungsten is extracted chemically from the crushed ore in a series of chemical reactions, titrations, washings, and filterings Tungsten mining countries are China, Russia, Portugal, Austria and Bolivia China is known to provide about 75% of the world's tungsten supply2 天前 Tungsten processing, preparation of the ore for use in various products Tungsten exhibits a bodycentred cubic (bcc) crystal lattice It has the highest melting point of all metals, 3,410° C (6,170° F), and it has high conductivity for electricity Owing to this unique combination of properties, it is used extensively as filaments for incandescent lamps, as electric contacts, and as Tungsten processing Britannica Tungsten Grinding Circuit The crushed ore from the fine ore bin is ground in a Rod Mill to free the minerals with as little sliming as possible The rod mill is of the special gratedischarge type which is extensively used for tungsten and many non Extracting Tungsten from Wolframite Gold Ore

Tungsten Mining Beneficiation International

The ore is first crushed and milled to liberate the tungsten mineral crystals Scheelite ore can be concentrated by gravimetric methods, often combined with froth flotation, whilst wolframite ore can be concentrated by gravity (spirals, cones, tables), sometimes in combination with magnetic separationTungsten scrap is a very valuable raw material due to its high tungsten content in comparison to ore Contaminated cemented carbide scrap, turnings, grindings and powder scrap are oxidized and chemically processed to APT in a way similar to that used for the processing of tungsten oresTungsten: extraction and processingMetalpedia Therefore, tungsten is extracted chemically from the crushed ore in a series of chemical reactions, titrations, washings, and filterings Tungsten mining countries are China, Russia, Portugal, Austria and Bolivia China is known to provide about 75% of the world's tungsten supplyTungsten element extraction method – surface mining

Tungsten processing Britannica

2 天前 Tungsten processing, preparation of the ore for use in various products Tungsten exhibits a bodycentred cubic (bcc) crystal lattice It has the highest melting point of all metals, 3,410° C (6,170° F), and it has high conductivity for electricity Owing to this unique combination of properties, it is used extensively as filaments for incandescent lamps, as electric contacts, and as Tungsten Ore Geology Scheelite, the principle ore of tungsten, has a specific gravity of approximately 60 (slightly heavier than iron sulfides) and is soft enough to be scratched with a knife It is usually buff or pale yellowishbrown and has a lustre that closely resembles some of the common nonmetallic minerals such a calcite, feldspar Tungsten Metallurgy Metallurgist Mineral Jigging for Tungsten in Scheelite Crushed ore is fed at a controlled rate by means of the Adjustable Stroke Feeder to the Mineral Jig Dilution water is added to provide a jig feed of 35% solids The Mineral Jig, which handles the unclassified feed, is equipped with “center drawoff” arrangement for automatic discharge of coarse (+10 mesh Extraction of Tungsten from Scheelite Ore

Tungsten Geoscience Australia

In 2018, Ore Reserves remained unchanged whilst production increased and, thus, reserve life decreased (Table 1) The reserve life, however, remains very large and this is attributable to the relatively small overall production rate Table 1 Australia's tungsten Ore Reserves, production and potential reserve life, 20022018 Most tungsten ores contain less than 15% WO 3 and ore dressing plants are always in close proximity to the mine The ore is first crushed and milled to liberate the tungsten mineral crystals Scheelite ore can be concentrated by gravimetric methods, often combined with froth flotation, whilst wolframite ore can be concentrated by gravity Tungsten (W) Properties, Applications best tungsten ore bucket crusher Best Tungsten Ore Bucket Crusher We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore metals likebest tungsten ore bucket crusher brauhaus

Tungsten: Industry standardsMetalpedia

World tungsten supply is dominated by Chinese production and exports China is also the world's largest tungsten consumer To conserve its resources and meet increasing domestic demand, the Chinese government issues the total amount of tungsten ore that can be Tungsten Ore spawns in the overworld between 0 and 35 Y It spawns in 10 clusters per chunk by default, and spawns a maximum of 8 ores per cluster It drops itselfTungsten Ore HBM's Nuclear Tech Wiki FandomTungsten scrap is a very valuable raw material due to its high tungsten content in comparison to ore Contaminated cemented carbide scrap, turnings, grindings and powder scrap are oxidized and chemically processed to APT in a way similar to that used for the processing of tungsten oresTungsten: extraction and processingMetalpedia

Tungsten element extraction method – surface mining

Therefore, tungsten is extracted chemically from the crushed ore in a series of chemical reactions, titrations, washings, and filterings Tungsten mining countries are China, Russia, Portugal, Austria and Bolivia China is known to provide about 75% of the world's tungsten supply2 天前 Tungsten processing, preparation of the ore for use in various products Tungsten exhibits a bodycentred cubic (bcc) crystal lattice It has the highest melting point of all metals, 3,410° C (6,170° F), and it has high conductivity for electricity Owing to this unique combination of properties, it is used extensively as filaments for incandescent lamps, as electric contacts, and as Tungsten processing Britannica In 2018, Ore Reserves remained unchanged whilst production increased and, thus, reserve life decreased (Table 1) The reserve life, however, remains very large and this is attributable to the relatively small overall production rate Table 1 Australia's tungsten Ore Reserves, production and potential reserve life, 20022018Tungsten Geoscience Australia

Tungsten (W) Properties, Applications

Most tungsten ores contain less than 15% WO 3 and ore dressing plants are always in close proximity to the mine The ore is first crushed and milled to liberate the tungsten mineral crystals Scheelite ore can be concentrated by gravimetric methods, often combined with froth flotation, whilst wolframite ore can be concentrated by gravity Critical material – Strategic Importance Atomic # 74, chemical symbol “W” Two economic tungsten minerals – Wolframite / Scheelite; Unlike most base and precious metals, Tungsten is largely not smelted to form metal due to its high melting point and is instead extracted from crushed ore using a series of chemical reactionsAbout Tungsten King Island Scheelite best tungsten ore bucket crusher Best Tungsten Ore Bucket Crusher We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment milling equipment mineral processing equipment and building materials equipment And they are mainly used to crush coarse minerals like gold and copper ore metals likebest tungsten ore bucket crusher brauhaus

Tungsten Ore HBM's Nuclear Tech Wiki Fandom

Tungsten Ore spawns in the overworld between 0 and 35 Y It spawns in 10 clusters per chunk by default, and spawns a maximum of 8 ores per cluster It drops itself Most often, tungsten is extracted from wolframite or scheelite ore that is crushed, cleaned, and processed to produce ammonium paratungstate (APT) The APT can be treated with alkalis to form multiple stages of oxides, known as tungsten trioxide (WO3), which can then be heated in a hydrogen atmosphere and reduced to produce tungsten metal powderProperties and Applications of Tungsten Wire Metal The ore from the mill feed bin will be sent to the ball mill for further screening The final crushed and screened material will undergo gravity concentration and flotation at the processing plant to obtain the wolframite concentrate, which will be dried and sold The recovery rate of the RHA tungsten processing plant is expected to be 85%RHA Tungsten Project Mining Technology Mining