What is Dry Concrete Batching Plant? MEKA

Dry concrete batch plant is a special plant used to mix concrete with compared to the other batching plants The dry mixed concrete plant has higher efficiency, but it must work with the mixer truck to mix the concrete MEKA dry batching concrete plant is Concrete batching plant manufacturers – AIMIX GROUP CO,LTD mainly supply customers stationary concrete batching plant, mobile concrete batching plant, rmc concrete plant, wet mix macadam plant and dry mix concrete batching plant According to output, they also can be classified into small concrete batch plant and mini concrete batching plantmanufacture process for dry batching plant DRY BATCH CONCRETE PLANTS GENERAL SPECIFICATIONS OF THE MEKA DRY BATCH CONCRETE PLANTS MEKA MB100D MEKA MB200D Plant Concerte Output (m /hyd /h) 100130 170220 Number of Aggregate Bins (n) 4 4 Batching for Truckmixer (m yd ) 912 912 Number of Cement Silos (100 tons) 2 3 Aggregate storage capacity (m yd ) 100/160130/210 100/160130/210MEKA DRY BATCH CONCRETE PLANTS new

Dry Mix Concrete Batching Plant of High Productivity

Compared with wet mix concrete batch plant, dry mix concrete batching plant is just like a concrete batching machine The whole working process is to batch raw materialsFirst, use wheel loader to transport all kinds of aggregates to aggregate batching machine, Dry batch concrete plant is different from wet mix applications Also called truck mixed or drybatched concrete manufacturing requires all of the raw ingredients to be charged directly into the truck mixer without mixing by the plant Dry batch concrete plants a typically simpler and more cost effective according to the wet mix typesDry Batch Concrete PlantYCZG Hello! I'm looking to build a dry mix concrete batching plant in Pima County, AZ to repurpose copper mining tailings We are looking to process 60100 cubic meters per hour of the dry mix concrete, batching/mixing the sand, two sizes of gravel, cement, and dried Dry Mix Concrete Batching Plant, Truck Mix Concrete

What Is The Batching Plant Process?

Before you can begin to understand the concrete batching plant process, it is important that you understand the difference between the two different kinds of batching plants There are ready mix plants, and these batching plants mix all of the ingredients together except for the liquid (water) at the plant The mixture is placed into [] Concrete Batching Plant Process Flow The work flow of the concrete mixing plant consists of four parts: weighing and feeding of sand and gravel, weighing and feeding of powder (cement, fly ash, etc), weighing and feeding of water and admixture, mixing and storageHow Does A Concrete Batch Plant Work Aimix Construction Before we understand the working or operation of a concrete batch plantIt is important to understand the basic components and structure of a batching plantWe have mobile concrete How does a concrete batch plant work Operation of

CONCRETE BATCH PLANT OPERATIONS

Section 1112 of AP42 (1/95) contains general information regarding concrete batch plant process descriptions, emission estimation techniques, emission factors, and control efficiencies An ARB study published in 1987 determined an average weight fraction for the PM10 content of concrete batch plant particulate emissions Cement, fly ash, andCompared with wet mix concrete batch plant, dry mix concrete batching plant is just like a concrete batching machine The whole working process is to batch raw materialsFirst, use wheel loader to transport all kinds of aggregates to aggregate batching machine, then raw materials will be conveyed to storage silo by belt conveyor, and at last, batched aggregates will be discharged into a Dry Mix Concrete Batching Plant of High ProductivityDry batch concrete plants are different from wet mix applications Also called truck mixed or drybatched concrete manufacturing requires all of the raw ingredients to be charged directly into the truck mixer without mixing by the plant Dry batch concrete plants a typically simpler and more cost effective according to the wet mix typesMB100/200D Dry Batch Concrete Plants MEKA

Dry Mix Concrete Batching Plant Professional

The dry mix concrete mixing plant is a specialpurpose concrete batch plant, which is mainly used for projects with low concrete quality requirements and long distances Compared to the common wet mix concrete batching plant, the dry concrete mixing plant is not equipped with a central mixer and is stirred by the mixing tanker during The dry batch concrete plant adopt vertical structure, the whole plant is moderate, the structure is compact and save cover area, it is also easy to install and transmove Dry batch concrete mixing plant technology has not passed through the mixing system of wet concrete batching plant, and the mixing process is completed in the mixing barrel Advantages of dry batch concrete plant Haoemei Before we understand the working or operation of a concrete batch plantIt is important to understand the basic components and structure of a batching plantWe have mobile concrete plants installations in Philippines’s city like: Bulacan, Cavite and PampangaIt is a machine that combines various ingredients like aggregates, sand, water, cement and additivesThese components are first How does a concrete batch plant work Operation of

Technical and environmental effects of concrete

While the central mixed concrete plant is sometimes also called “wet batch system”, the “dry batch concrete plant” doesn’t use a fixed mixer All ingredients excepting admixture are poured into a buffer, which directly led them into the truck mounted revolving mixer that ensure both mixing and transport ( Fig 1 b)A batching plant, also known as a concrete mixing plant can hold a large amount of water, gravel, sand, and rocks which are used to create amounts of fresh concrete You can choose from two types of mixing plants: The central mix plants (wet mix) or the readymix plant (dry Should You Use a Dry Mix Concrete Batching Plant for Figure 1 in the Appendix shows a typical dry mix concrete batch plant layout The ideal size for setting up is plant is 2,950m2, this set up will include a laboratory for quality control, a site office for staff and other facilities such as workshop and weighbridge on material control Process Flow of Dry Mix PlantWet Mix and Dry Mix Concrete: Cost and Quality

Application Package For CONCRETE BATCH PLANT

(1) Sources that manufacture dry concrete or cement products (such as cinder block, concrete pipes, etc), or (2) Sources that use dry concrete or Portland cement in a manufacturing process Part II Definitions A “Concrete Batch Plant” means a plant that mixes water, Portland cement, fine and coarse aggregates to form wet concrete Normally, a concrete batch plant can be of two types, depending upon how the mixing is done and when the concrete reaches the job site The first is a readymix plant, which involves combining all ingredients for the concrete except for water, which is added as the final ingredient during transportation to a job siteWhat is a concrete batch plant? Big D Ready MixCompared with wet mix concrete batch plant, dry mix concrete batching plant is just like a concrete batching machine The whole working process is to batch raw materialsFirst, use wheel loader to transport all kinds of aggregates to aggregate batching machine, then raw materials will be conveyed to storage silo by belt conveyor, and at last, batched aggregates will be discharged into a Dry Mix Concrete Batching Plant of High Productivity

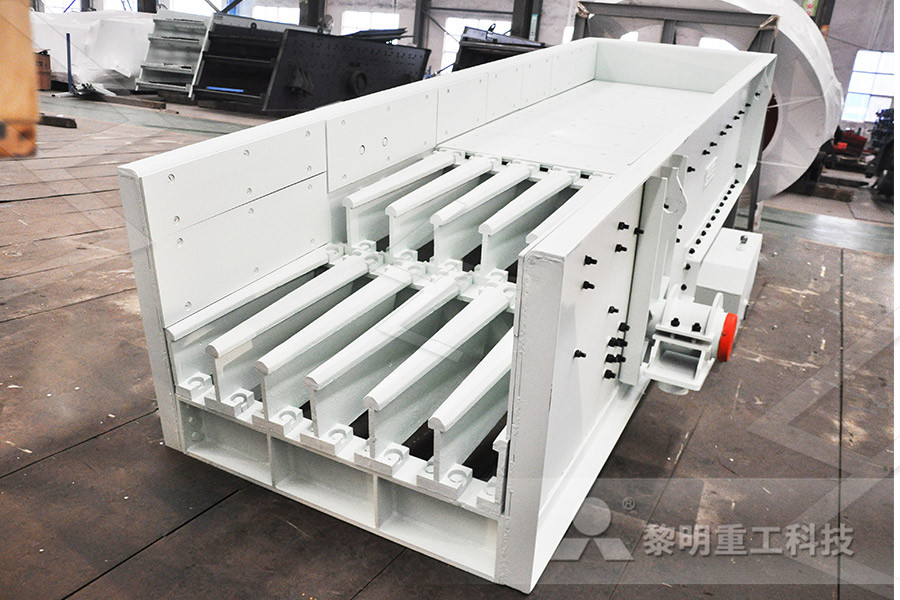

Dry Concrete Batching Plant, Transit Mix Concrete

Dry Mix Concrete Batching Plant is a kind of concrete plant for special application that is utilized in projects with low concrete quality requirements and long distances Compared with wet concrete plant, the dry concrete batching plant mixes concrete by concrete truck mixer, so it also be called as "Transit Mix Concrete Batch Plant" When the dry concrete batching plant working, each 13 小时前 As the name suggests, dry mix concrete plant has no concrete mixers, which often produce dry batch concrete in the production process Then, the dry concrete is mixed inside a mixer truck in the transportation process, and lots of concrete mixer truck are involved in this production process of dry batch concrete plantDry Batch Concrete Plant concrete batching plant Features of Dry Mix Concrete Batch Plant The particular thing of a dry type concrete batching plant is that the materials are mixed without water Water will be added in the process of transportation by concrete mixer truck, so the cooperation between dry mix plant and mixer truck is important There isn’t a concrete mixer included in the Dry Mix Concrete Plant for Sale Professional Supplier

Dry Batch Plants Archives Concrete Batch Plants

BMH specializes in manufacturing highperformance concrete batch plants, Dry Batch Plants 250+ yd³/hr High Prod 100% Tailored to Your Needs Gravity or low profile, you choose High Production Up to 250 yd³/hr (191 m³/hr) Impressive Quality A dry batch plant to last decades 180 yd³/hr Med+ Prod PreEngineered with Lots of Options The mixing process of batching plant operation includes the loading method, the mixing, the discharge method, the mixing time, and the mixing energy The loading method is composed of the loading constituents into mixer order and the loading period duration The duration of this period depends on how long the constituents are mixed dry before the addition of water and how fast the constituents The Concrete Mixing Process in Batching Plant Figure 1 in the Appendix shows a typical dry mix concrete batch plant layout The ideal size for setting up is plant is 2,950m2, this set up will include a laboratory for quality control, a site office for staff and other facilities such as workshop and weighbridge on material control Process Flow of Dry Mix PlantWet Mix and Dry Mix Concrete: Cost and Quality

1112 Concrete Batching US EPA

Concrete masonry, another type of manufactured concrete, may be best known for its conventional 8 x 8 x 16inch block In a few cases concrete is dry batched or prepared at a building construction site Figure 11121 is a generalized process diagram for concrete batching The raw materials can be delivered to a plant by rail, truck or barge Ready Mix Concrete Batch Plant For Sale Ready mix concrete plant belongs to concrete batching plant It is the important type for dealing with concrete operation The entire design adopts the computer control Of course, you can also operate the machine automatically or manually So, it can be easy to operate and easy to masterReady Mix Concrete Batching Plant Good Batching Whereas the process technology impacts the mixdesign strategy, it seems obvious that manufacturing process is prone to evolutions This article presents a method to compare environmental and economical consequences of different technological solutions on the basis of the influence on the cement consumption needed for a given concrete performanceTechnical and environmental effects of concrete