feeding head of cement mill Products

Feeding Head of Cement Mill By Editor on 14th February 2014 in Feeding Head of Cement Mill About Editor View all posts by Editor Raw Mill Feeding Cement Plant Optimization Mill Feeding Hoppers Hoppers for limestone/ clay/ iron ore serve the purpose of providing a buffer storage for mill feed and a convenient arrangement for feeding to A wide variety of cement feeding pump options are available to you, such as electric, pneumatic, and hydraulic You can also choose from food and beverage industry, automotive industry, and industrial boilers cement feeding pump, as well as from ce, rohs, and erp cement feeding pump, and whether cement feeding pump is multistage pump, singlestage pump, or piston pumpcement feeding pump, cement feeding pump Kiln Feed Bin: A mixing bin with a capacity of half to onehour kiln feed, mounted on load cells, facilitated with level switches, serving a purpose of maintaining a constant head (pressure/level) of raw meal inside bin to ensure that there are no fluctuations in the rate of discharge due to change of head/level of material In addition to provide a constant head and a mixing purpose, kiln feed bin mounted on load Kiln Feeding Cement Plant Optimization

What You Need to Know About Rotary Feeders In

Rotary Feeder Rotary Valve Applications in Cement In most applications, no matter the industry, rotary feeders and valves have one or two functions The two 7 Silo feeding with steepangle conveyor • Inclination up to 45° The standard DeepDrawn Pan Conveyors fitted with baffle plates allows for conveying at inclinations up to 45° The standard chain program allows for conveying heights up to 90 m Pan Conveyor with Deep Drawn Pans and Conveying and Storing in the Cement Industry Wastes can be in different feeding point into the cement production process, adding the location should undertake choosing according to the characteristics of solid waste, the most common of which are: high temperature period, including rotary kiln kiln head main burner add and close the door cover shots with a little: high temperature segments, including decomposition furnace, tail smoke From which point can the waste enter the cement

Tick attachment cement – reviewing the mysteries of a

Attachment cement is a rapidly hardening substance produced by the salivary glands of Ixodidae in preparation for and during feeding Before cement secretion is finished, High quenching speed has the following advantages: 1) prevents the clinker from pulverizing due to C 2 S transformation; 2) makes the clinker ball produce internal stress and improves its grindability; 3) reduces the crystallization of C 3 A in clinker and improves the sulphuric acid resistance of finished cementCement Clinker Quality Control During Clinker Feeding frequency also has an impact on bunk space Onceaday feeders may require more space for feeding than two or more times per day feeders, and receiving pens should have 24 inches per head of bunk space to avoid crowding and ensure feed intake upon arrivalFEEDLOT DESIGNS COSTS AND CONSIDERATIONS

Ghayyur Ali Head Of Production Hail Cement

Head Of Production at Hail Cement Company Pakistan 500+ connections Join to Connect Hail Cement Company University of Engineering and Technology, Lahore Report this profile Activity Finally received my Certificate of CIMA Membership, Happy Find here Cement Feeding Machine, Cement Feeding Pump manufacturers OEM manufacturers India Get Contact details address of companies manufacturing and supplying Cement Feeding Machine, Cement Feeding Pump across IndiaCement Feeding Machine Cement Feeding Pump Kiln, considered as heart of the cement plant needs to be fed with consistent raw meal at uniform feed rate No mater how much consistent and perfect is your kiln feed quality from blending silo, variation in feed rate can disturb badly kiln operation stability, clinker quality and heat consumptionKiln Feeding Cement Plant Optimization

Tick attachment cement – reviewing the mysteries of a

At feeding sites of female Rhipicephalus sanguineus no substantial increase in the amount of cement was observed after 24 h of attachment (Theis Budwiser, 1974); however, secondary cement production was observed in another report on this species (Moorhouse, 1969) Head cement could leave a foreign scent in the water, especially if tied up the night before A clean whip finish is more than durable enough anyhow, especially if performed a few times Even without head cement, the head of the fly will most likely outlast the life of the hookFly Tying Tip Tying Bonefish Flies Without Head Cement rotary kiln, also called clinker kiln, can be divided into dryprocess cement kiln and wetprocess cement kiln according to the cement production technologyDryprocess cement rotary kiln is mainly used to calcine cement clinker As the core equipment of NSP cement production line, cement rotary kiln is consist of shell, supporting device, transmission device, lubrication device, moving Cement Rotary Kiln, Rotary Kiln Cement Kiln AGICO

FEEDLOT DESIGNS COSTS AND CONSIDERATIONS

Feeding frequency also has an impact on bunk space Onceaday feeders may require more space for feeding than two or more times per day feeders, and receiving pens should have 24 inches per head of bunk space to avoid crowding and ensure feed intake upon arrival Choose a feeding system flexible enough to allow for changing the rations you use Although many approaches to this problem show success, four particular details of bunk and headrail design appear to be helpful in prevention: throat height at the recommended height (not too low) reduced feed opening: 20 cm (8 in) maximum, 175 cm (7 in Low Labour Feeding Systems and Bunk Design for Our oral gavage feeding tubes are designed to be flexible and reduce trauma on lab animals while eliminating the cost of cleaning and cross contamination We offer a wide variety of feeding tubes for mice and rats including polypropylene, polyurethane and steel feeding tubesOral Gavage Feeding Tubes for Mice Rats Instech

STRATEGIES FOR DRY SEASON FEEDING OF ANIMALS

Strategies for dry season feeding of animals in Zambia Some of the main methods of coping with the nutritional stress induced by the dry season in Zambia have been: Conservation of maize and sorghum stover for feeding to the most vulnerable stock (especially milking cows, weaners and traction stock) Use of multinutrient blocks in feeding Imagine your head’s heaviness as an object, such as a cement block or brick Then, still with your eyes closed and concentrating, picture that cement block being lifted and taken away It may sound strange, but it can help your head feel clearer and lighter 2 Rest Your Eyes Heavy head feelings and migraines can be worsened by straining Head Feels Heavy: 7 Causes and TreatmentsKiln, considered as heart of the cement plant needs to be fed with consistent raw meal at uniform feed rate No mater how much consistent and perfect is your kiln feed quality from blending silo, variation in feed rate can disturb badly kiln operation stability, clinker quality and heat consumptionKiln Feeding Cement Plant Optimization

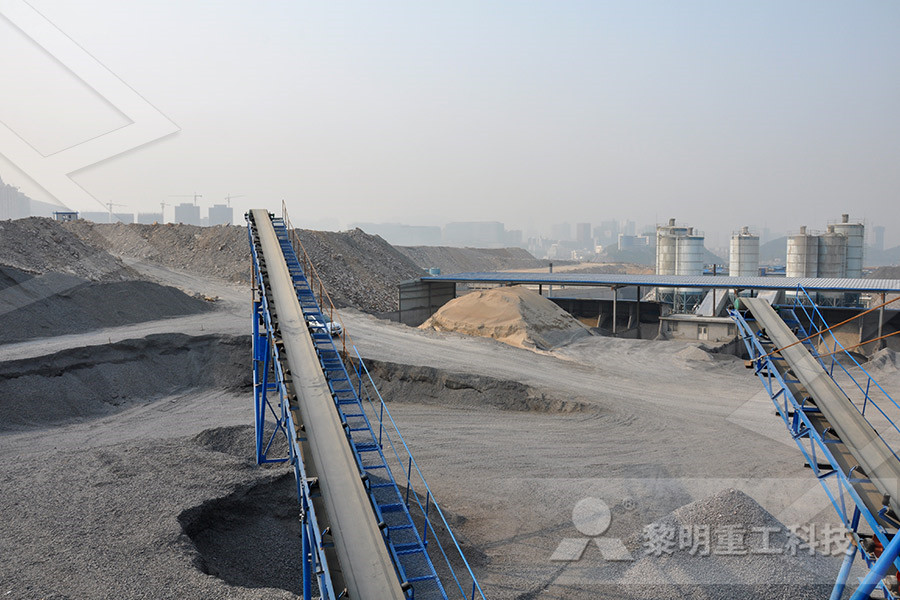

Feeding Conveyor Patel Corporation

Feeding Conveyor products include various types of aggregate feeding systems for batching plants of different design and manufacturers Aggregate feeding conveyor with rotary chute arrangement for compartment batching plant and Swivel conveyors for inline type aggregate storage bins are some of them Quality and Standard bought out items like, motors, gearboxes, rubber belts are important to At feeding sites of female Rhipicephalus sanguineus no substantial increase in the amount of cement was observed after 24 h of attachment (Theis Budwiser, 1974); however, secondary cement production was observed in another report on this species (Moorhouse, 1969)Tick attachment cement – reviewing the mysteries of a with particular regard to feeding and transfer in belt conveying operations 2 BOUNDARY FRICTION, COHESION AND ADHESION 21 Boundary or Wall Yield Locus For chute design, wall or boundary surface friction has the major influence It has been shown that friction depends on the interaction between the relevant properties of the bulk solid and CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND

AnaLog Services PEK SIE CBT Care and Feeding

The Care and Feeding of SIE Cement Bond Tools The following material was provided by Paul Knight to some of his customers a few years back Paul is a legendary character in the history of the oil well logging industry and has "forgotten more than the Head cement could leave a foreign scent in the water, especially if tied up the night before A clean whip finish is more than durable enough anyhow, especially if performed a few times Even without head cement, the head of the fly will most likely outlast the life of the hookFly Tying Tip Tying Bonefish Flies Without Head Feeding frequency also has an impact on bunk space Onceaday feeders may require more space for feeding than two or more times per day feeders, and receiving pens should have 24 inches per head of bunk space to avoid crowding and ensure feed intake upon arrivalFEEDLOT DESIGNS COSTS AND CONSIDERATIONS

Variations and factors that influence the formation of

Each of the cement kiln systems consisted of a chimney, two bag filters (one at the kiln head and one at the back end of kiln), an air quenching cooler (later simply called the cooler), a boiler at kiln head, a coal mill, a rotary kiln, a precalciner, a fivestage cyclone preheater (C1 to C5), a suspension preheater (SP) boiler, and a humidifier tower Table 1 Supplementary feeding recommendations Available feed Class of stock Supplement Frequency Cows and calves, dry adult stock Urea/molasses, mix 60 g urea/head/day OR Highprotein grains, 05–10 kg/head/day OR Protein meals, 03–07 kg/head/day Continuous access Feed every second day Feed twice weekly Plentiful dry feedSupplementary feeding of cattle NSW Department of Strategies for dry season feeding of animals in Zambia Some of the main methods of coping with the nutritional stress induced by the dry season in Zambia have been: Conservation of maize and sorghum stover for feeding to the most vulnerable stock (especially milking cows, weaners and traction stock) Use of multinutrient blocks in feedingSTRATEGIES FOR DRY SEASON FEEDING OF ANIMALS