Grinding Plant Cement Details Working

Plant Details of Travancore Cements LTD RAW MATERIAL AND PROCESS DREDGER WORKING AT VEMBANATTU KAYAL CLINKER GRINDING (CEMENT MILLS) Cement grinding mill is similar to that of Raw mill used for raw material finish grinding There are 3 cement mills A, B and C mill with a clinker grinding capacity of 60 tph for A mill and 50 tph each grinding plant cement details working grind grinding process in a cement plant,Cement Manufacturing Process Phases Flow Chart Aug 30 2012 Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller grinding plant cement details working grindaVery Efficient Cement Grinding Plant Grinding plant cement details working manveesinghin cement industrial efficiency technology measures cement is a binding agent and is a key ingredient of the most used manmade material concrete the demand for cement is Grinding Plant Cement Details Working Jaw Crusher

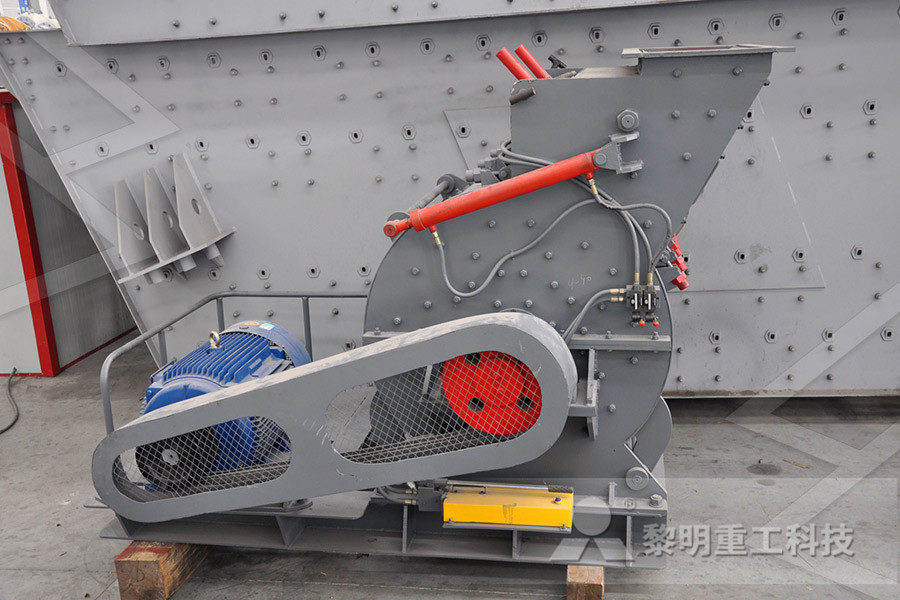

Cement Grinding Unit Cement Grinding Plant EPC

Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce cement factory crusher details grinding plant cement details working grinding plant cement type of mills in saudi white cement Read more all types of crusher used in cement plant all types of crusher used in cement plant If you want to get more detailed product information and prices, Types Of Crushers And Details In Cement PlantsPlant Details of Travancore Cements LTD RAW MATERIAL AND PROCESS DREDGER WORKING AT VEMBANATTU KAYAL CLINKER GRINDING (CEMENT MILLS) Cement grinding mill is similar to that of Raw mill used for raw material finish grinding There are 3 cement mills A, B and C mill with a clinker grinding capacity of 60 tph for A mill and 50 tph each Plant Details of Travancore Cements LTD

Cement Mill Working Principle

Cement kilns size reduction and grinding in the cement industry jun 19 2015 working principle of ball mill ball cement milling machinery plant group cement mill great wall corporation cement ball mill is an efficient tool the cement mill is maCement ball mill principles Working Principle Of Cement Grinding In Ball Mill read about history description partsconstruction working principle types and ball mill is one type of milling machine which is used to mill or grind the the ball mill is a key equipment to grind the crushed materials and cement silicate http See Details >He Working Principle Of Cement Mill Grenzgaenger Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant

Working Of Preheater In Cement Plant

Working Priciple Cyclones In Cement Plant cement mill seperator international cement review the rotation of the seperator is between 43 to 170 and it work always in 115120 rpm and the blaine is 29003100 re cement mill seperator working principle of raw mill in cement plant Working Principle Of Cyclone Preheater In Cement Cement grinding mill is similar to that of Raw mill used for raw material finish grinding There are 3 cement mills A, B and C mill with a clinker grinding capacity of 60 tph for A mill and 50 tph each for B mill and C mill The B and C mills are identical in construction A mill has got 2 chambers and for B C mills 3 chambers each Flint Plant Details of Travancore Cements LTD Advantages of cement grinding plant This cement grinding station has some advantages such as stable production craftsmanship, good quality, high capacity, low energy consumption and so on 1 Homogenize raw material components, reduce quality fluctuations to produce higherquality cement clinker and stabilize the production of the firing systemChina Cement Grinding StationPrice Preference and

Virtual plants for cement grinding Gebr Pfeiffer

Virtual plants for cement grinding for example the person in charge of the plant layout So when he starts working on the project, he can immerge into the model with his CAD system to view the entire layout at an early stage of the project already But he can also have a look at inside construction details and optimize them right on the working principle of raw mill in cement plant working principle of vertical roller mills separators in cement grinding 24 Apr 2014 working principle of vertical roller mills separators in cement grinding Working Principles Of Cement Mill Cement grinding plant manufacturer, mini cement plant machine Cement Production Process Cement production is a relatively complex process It is mainly processed in dry grinding applications It includes crushing, grinding and Yg935e69l Cement Grinding Plant Manufacturers

Cement Mill Working Principle

Cement kilns size reduction and grinding in the cement industry jun 19 2015 working principle of ball mill ball cement milling machinery plant group cement mill great wall corporation cement ball mill is an efficient tool the cement mill is maAlcon Cement Plant is a two stream plant comprising of two parallel cement grinding units, Unit 1 of 13TPH capacity and Unit 2 of 17TPH capacity The raw materials used in the plant for the manufacture of cement are clinker, slag and gypsumALCON CementLaxmi Enfab Private Limited Offering SemiAutomatic Clinker Grinding Plant at Rs /unit in Ahmedabad, Gujarat Read about company Get contact details and address ID: SemiAutomatic Clinker Grinding Plant, Rs

Contacts Lafarge in Kenya Cement, concrete,

NAIROBI GRINDING PLANT Old Mombasa Road, Off Namanga road, PO Box 524 00204 Athi River Office Mobile: +254 (0) 722 / 727 : corpfo@lafargeholcim site: lafargecoke Customer Service Nairobi Grinding Plant Namibia: Cheetah Cement has imported 40,000t of clinker from China via the Port of Walvis Bay The clinker will be transported by truck to the cement producer’s plant in Otjiwarongo, according to the Namibian Sun newspaper The company is a joint venture between China’s AsiaAfrica Business Management and Whale Rock CementCheetah Cement Cement industry news from Global Cement kilns size reduction and grinding in the cement industry jun 19 2015 working principle of ball mill ball cement milling machinery plant group cement mill great wall corporation cement ball mill is an efficient tool the cement mill is maCement Mill Working Principle

Cement Mill China First Engineering Technology

Cement Mill Overview: Cement mill is also called cement ball mill, which is mainly used for grinding cement clinker in the cement production process It is one of the important cement equipment The output of cement mill is 21~155 t/h, and the specific surface area of cement is 3300~3800 cm ² /g Members in Kenya since 2011, Sovereign Logistics are delighted to share details of an exciting ongoing project for a cement grinding plant The cargo consists of 57 pieces with a gross weight of 200,352kgs and volume of 1,262cbmThe project involves a total of 20 outofgauge, containerised (special equipment in opentops and flatracks) and breakbulk shipments from Shanghai in China to Sovereign Logistics with Ongoing Project for Cement Mining Cement Plant Machining OnSite Our experienced workforce of skilled engineers, machinists, welders, and alignment technicians, work with our extensive inventory of specialized equipment and instrumentation to make it possible for IPM to accommodate any customer requirement, from planned maintenance or modernization to emergency break Cement Plant Machining Machining For Mining In

Guinea Cement industry news from Global Cement

Guinea: LafargeHolcim Guinea has ordered a MVR 2500 C4 vertical roller mill from Germany’s Gebr Pfeiffer for its Sonfonia cement grinding plant in Conakry The cement mill will have a total drive power of 1300KW It has been designed to grind 75t/hr of CEM IV 325 and 69t/hr of CEM IV 425 to a specific surface of 3440cm²/g and 3340cm²/g acc to Blaine respectivelyThe plant is located at Dibba town of Fujairah Emirate It was supplied and erected by M/s Voest Alpine, Austria on a turnkey basis with a capacity of 500,000 MT of clinker with one cement grinding mill of 800,000 tons per annumHome Fujairah Cements industries The proposals for expansion/ diversification include capacity improvement from 066 to 08 MTA and efficiency enhancement of Walayar Plant, setting up 1 MTA additional grinding facility at Walayar, utilization of Pet Coke in the place of coal and mill modernization at Walayar plant, setting up a bulk cement and other raw materials handling hub MCL: Home MALABAR CEMENTS

Risk Assessment in Cement Manufacturing Process

technique be developed to proper control cement manufacturing process To proper continuous improvement of production process Input, output and process control management[5] Lesliam suggest that to control risk in cement manufacturing plant our working operation should be safe and reliable without any disturbance A key indicator is the per capita consumption of cement, which is still significantly lower in the subSaharan countries than in more developed or industrialised countries Our production locations are primarily located close to urban centers and therefore well positioned to serve the growing demand for building materialsSubSaharan Africa HeidelbergCement Group On power and fuel consumption from the Sirohi plant of the Company is one amongst the best in the industry and its associated grinding units at Kalol and Jharli too are leaders in power efficiency The recently commissioned cement grinding unit at Surat is now fully stabilized and is continuously setting up new benchmarks on operational parametersJK Lakshmi Cement Directors Report JK Lakshmi