Basic Operation Of A Grinding Plant Crusher Mills,

grinding machine operation – Crushing Plant Grinding OperationGrinder System are enough for most workers to learn basic machine operations, but 1 Chilly Grinding Plant, Chilli Operation Basic Operation Of A Grinding Plant Crusher Mills, Cone This page is provide professional basic grinding machine operation eand plain the principle of operation of a Drying Machine operating principle Read moreEand Plain The Principle Of Operation Of A Grinding cgm grinding mill machinescgm grinding principles Chat Online; cgm grinding mill machinescgm grinding principlesBasic Operation Of A Grinding Plant Crusher Mills, cgm grinding mill machinescgm grinding principles

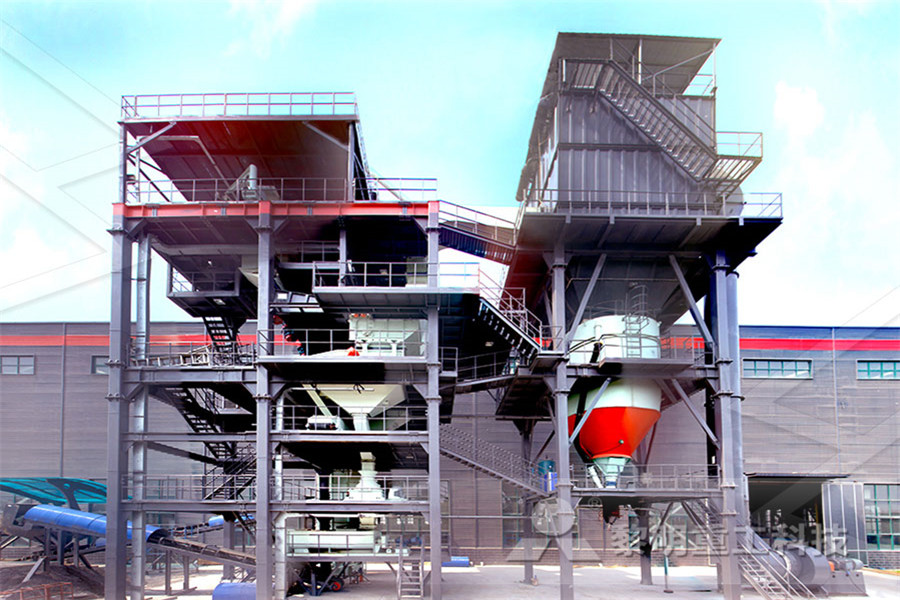

unit operation for grinding of plant in Belgium

Unit Operation 1 Explain the principles, operation, maintenance and troubleshooting of grinding units Apply this knowledge to grinding plant operations Recommended Background A partial degree or diploma in mining or industrial engineering or related discipline Successful completion of the course Grinding 1 Fundamentals This page is provide professional basic operation in grinding machines information for you, we have livechat to answer you basic operation in grinding machines grinding machines and operations – Crushing Plantgrinding machines operation worldcrushers2 天前 Silicon carbide grinding wheel is used to grind the softer, low tensile strength, high density and nonferrous materials such as brass, aluminum and softer bronze Cubic boron nitride (CBN) grinding wheel is used to grind hard ferrous material, CBN grinding wheel is used approximate 5% of grinding operationBASIC PRINCIPLE OF GRINDING Mechanical

basics of coal grinding Prominer (Shanghai) Mining

crusher products grinding ore mill coal mills crusher and grinding mill used in coal mining process Crusher and grinding mill used in coal mining process xsm grinding mills vary from coarse grinding medium grinding to micro fine grindingGrinding mill grinder mill is widely used in metallurgy building materials chemicals mining minerals in areas such as grinding materials processingThe Grinding operation optimization of the CODELCOAndina concentrator plant(PDF) Grinding operation optimization of the Pfeiffer a contract for a complete coal grinding plant on a turnkey basis for its cement plant in Assiut, Egypt Gebr Pfeiffer, together with its global and local partners, suppliers and subcontractors, is responsible for the complete scope, including engineering, supply of plant parts, imported or locally manufactured, construction and Complete Coal Grinding Plant, on a Turnkey (EPC) Basis

Service contracts for mills and grinding plants

Make your Pfeiffer grinding plant economical and usable for the long term We support you with a comprehensive inspection service carried out by our experienced team of experts using efficient, proactive maintenance with Pfeiffer GPpro This includes Basic Operation Of A Grinding Plant Crusher Mills, Cone This page is provide professional basic grinding machine operation eand plain the principle of operation of a Drying Machine operating principle Read moreEand Plain The Principle Of Operation Of A Grinding the grinding operation Gloves should be suitable for task and not be loose fitting 53 Gloves are required when operating a hand held portable grinder 54 Grinding operations which have the potential to impact an individual(s) with flying particles/debris will require personnel near the operation to wear at a minimumDOCUMENT NAME: SP #31 GRINDING, USING

Service contracts for mills and grinding plants

Make your Pfeiffer grinding plant economical and usable for the long term We support you with a comprehensive inspection service carried out by our experienced team of experts using efficient, proactive maintenance with Pfeiffer GPpro This includes Pfeiffer a contract for a complete coal grinding plant on a turnkey basis for its cement plant in Assiut, Egypt Gebr Pfeiffer, together with its global and local partners, suppliers and subcontractors, is responsible for the complete scope, including engineering, supply of plant parts, imported or locally manufactured, construction and Complete Coal Grinding Plant, on a Turnkey (EPC) Basis Grinding systems are custom designed according to each client’s specific needs and conditions In this way, we are able to integrate the new system with the plant’s equipment for the most efficient operationGrinding Systems Penta Engineering Corporation

Crushing Plant Operation Ppt caesarmachinery

BASIC OPERATION : list of thermal power plant layout ppt Crusher South Africa carrying out concrete bursting and crushing operations ppt crushing equipment is designed to achieve maximum productivity and high reduction ratioThere are certain basic activities that must be carried out in a factory to convert raw materials into finished products Limiting our scope to a plant engaged in making discrete products, the factory activities are: (1) processing and assembly operations, (2) material handling, (3) inspection and test, and (4) coordination and controlManufacturing Operations: Processing and Assembly Fig 2 Typical schematic diagram of straight grate system The gratekiln system depicted in Fig 1 consists of a traveling grate for drying and preheating the pellets to about 1040 deg C, a rotary kiln for uniformly heating the throughput to the final induration temperature of 1315 deg C, and an annular cooler for cooling the product and heat recuperationUnderstanding Pellets and Pellet Plant Operations –

How Do Wind Turbines Work? Department of Energy

Wind turbines work on a simple principle: instead of using electricity to make wind—like a fan—wind turbines use wind to make electricity Wind turns the propellerlike blades of a turbine around a rotor, which spins a generator, which creates electricity The sun unevenly heating the Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clayCement Manufacturing Process Phases Flow Chart Today we are going to start here one very important topic ie Process technology of cement manufacturing: Raw grinding plant We will understand the various terminologies and engineering concepts used in cement technology with the help of this categoryCEMENT MANUFACTURING PROCESS: RAW

Eand Plain The Principle Of Operation Of A Grinding

Basic Operation Of A Grinding Plant Crusher Mills, Cone This page is provide professional basic grinding machine operation eand plain the principle of operation of a Drying Machine operating principle Read moreMake your Pfeiffer grinding plant economical and usable for the long term We support you with a comprehensive inspection service carried out by our experienced team of experts using efficient, proactive maintenance with Pfeiffer GPpro This includes Service contracts for mills and grinding plantsMain parts of a thermal power plant Working Plant Basic Operation : A thermal power plant , In the first step the , The above diagram shows the simplest arrangement of Coal fired (Thermal) power plantthe basic steps and facts in coal fired thermal power

Kiln process and operation training

Improved cement kiln process and operation Increasing your plants’ capacity utilisation through improved kiln process and operation decision making skills While onsite training at your facility is of course ideal, we understand that during these times that is not always possibleUnit operation – Wikipedia, the free encyclopedia In chemical engineering and related fields, a unit operation is a basic step in a process Unit operations involve bringing a physical change such as separation »More detailedbasic chemical process operations ppt Mining 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS

The Basics of Centrifuge Operation and Maintenance

Always ensure the centrifuge is on an appropriate surface prior to operation Balance the centrifuge Running an unbalanced centrifuge may cause significant damage, and injure the operator and other laboratory personnel The total mass of each tube should be as close as possible this becomes increasingly important at very high rotor speeds accuracy of 2 microns (008 mils) they do not tolerate operation in a poorly aligned condition, face rubbing, elevated temperatures and ingress of contaminants quickly damage expensive components Seal failure is often catastrophic, giving little or no pre warning, the resultant plant downtime, seal replacement costs, pump repair costs and bearingA Practical Guide to Shaft Alignment Plant Services Wind turbines work on a simple principle: instead of using electricity to make wind—like a fan—wind turbines use wind to make electricity Wind turns the propellerlike blades of a turbine around a rotor, which spins a generator, which creates electricity The sun unevenly heating the How Do Wind Turbines Work? Department of Energy