Cement plant motors up to 13,8kV and 20000 kW

Cement mills, fans, shredders in the production of cement, particularly large and efficient motors are required for the most diverse processes MENZEL offers individual motor solutions for all applications in the cement industry up to 138 kV and 25 MW In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications The criteria for motor selection includes:Selection of AC Induction Motors for Cement Plant Abstract: In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applicationsSelection of AC Induction Motors for Cement Plant

Selection of AC Induction Motors for Cement Plant

In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications The criteria for motor selection includes: operating conditions, driven equipment starting requirements Although motors may appear to be the least complicated component in the specification of cement mill equipment, this article shall try to demonstrate that cement plant applications present an immense matrix of application criteria to properly specify and design motorsSelecting AC induction motors for cement plant cement plant were used to identify the model's parameters The most common use of portland cement is in the production of concrete Concrete is a justified by the fact that a considerable amount of energy supplied by the mill's motor isapplication of motor in cement mill

The essentials of electrical systems in cement plants EEP

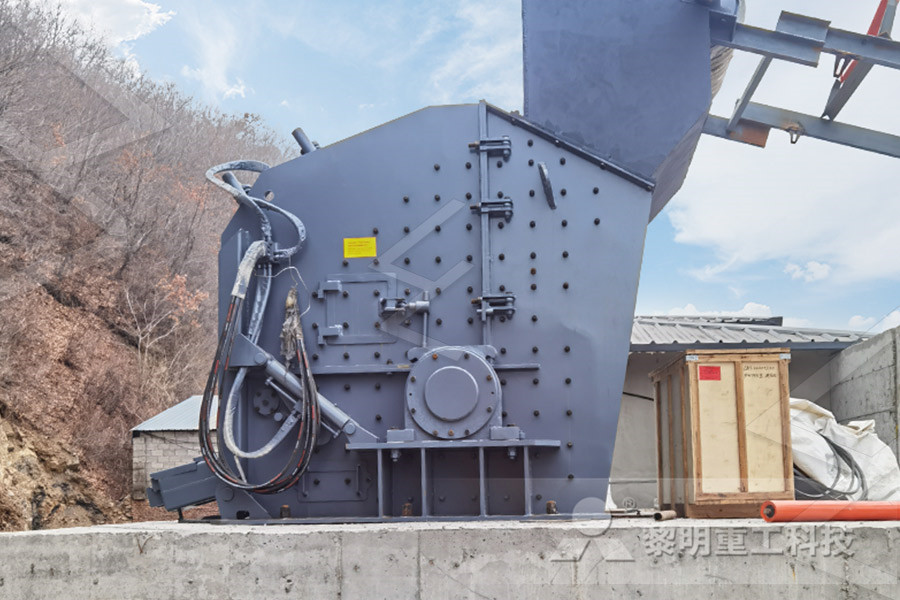

In the last 25 years, variable speed drives (VSD) have been used more frequently in the cement industry The main reason was to save energy in the production process Generally speaking, variable speed motors would be used for electric motors All electric drives, including motors and control wiring associated with machinery or equipment commonly used in the manufacturing areas of cement plants are covered Recommendations are not intended to apply to power distribution circuits These recommendations apply to electrical equipment having a supply voltage of 13 800 V or lessIEEE 4991997 IEEE Recommended Practice for Cement types of crushers in cement plant machine used to crush Home>>Case Line>types of crushers in cement plant cement plants 21 35 Details of Fugitive Emission Management for Li ne crusher, cement plant and other Types Of Crushers And Details In Cement Plants

How many cement plants are producing in the USA 2020

Coplay Cement Company From 1893 to 1904 the nine vertical kilns of the Coplay Cement Company were used for the production of portland cement Built as an improvement in kiln technology over the bottle or dome kiln then in use, the 90 foot high vertical kilns had the advantage of producing a higher quality product than dome kilns and produced it on a continuous basis as well In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications The criteria for motor selection includes:Selection of AC Induction Motors for Cement Plant In the last 25 years, variable speed drives (VSD) have been used more frequently in the cement industry The main reason was to save energy in the production process Generally speaking, variable speed motors would be used for electric motors listed in Table 1 The essentials of electrical systems in cement plants EEP

Cement Plant an overview ScienceDirect Topics

The mass and energy balances for the cement plant concepts with carbon capture were used furthermore to evaluate the key plant performances The designs were optimized by performing a heat integration analysis (using pinch technique) for maximization of the overall energy efficiency (Smith, 2005)As an illustrative example, Figure 1 presents the hot and cold composite curves for the calcium The IE1 motors of the Standard low voltage series by OME Motors are threephase asynchronous motors with an aluminum and / or cast iron body IE1 standard Low Volt motors are mainly used in the oil, chemical, metallurgical, cement and paper industries; they can be used in combination with pumps, fans, compressors and general machinery The OME electric motors are particularly performing and IE1 STANDARD LOW VOLTAGE ELECTRIC MOTORS in There are several types of motors to choose from when selecting motors for large HP (2000 HP 10000 HP) cement plant applications including; squirrel cage induction motors, wound rotor induction motors, PAM induction motors, synchronous motors, and DC motors, all of which have their own advantages and disadvantages This paper will compare the operational characteristics of the induction Considerations in the Selection and Application of AC and

Electric Motors for Machinery: It’s Versatility and

Today, electric motors can be as little as you want or as big; depending on their purpose, capabilities, and applications They can be utilized to pump up oils, to crush stones and cement, to purify waters, and so much more They can even be used to generate electricity, especially by placing them in turbines of the wind power generations A periodic article by Folkert Haag on the cement and concrete industry printed in the November, 2015 issue of International Cement Review Excitement around what has been coined “the Internet of Things” continues to grow as manufacturers, vendors, and customers begin to realize the substantial benefits of embedding sensors in everything What IoT and the Digital World Mean for the Cement All the ACC Cement Plants use the cutting edge technologies and services which in turn produce high quality cement brands Set up in the year 1936, ACC has always worked dedicatedly to produce some of the best brands of cement and its business strategy is based on providing the best of products to the changing consumer market in the country and the worldACC Cement Plant, Locations and Features of ACC Plant

Omkar Group of Companies – Official site

Also Motors/ Gear Boxes used in utility like Boilers, Large Compressors, Refrigeration systems, Air Conditioning systems, Water Treatment Plants, Cooling Towers etc Fertilizer Industries Refurbishing of all types of LT/HT motors Gear Boxes used for Composting Sale Buy UnUsed Machinery, Used Machinery Industrial Plants Are you looking for working condition used machinery, second hand machinery, complete running industrial unit, a sick unit or do you have something to offer yourself then you are at the right placeused machinery, suppliers, second hand machines, used In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications The criteria for motor selection includes:Selection of AC Induction Motors for Cement Plant

Medium voltage motors up to 138 kV and 25 MW

Medium voltage motors are used in all industries in which heavy loads are moved or work is carried out in conjunction with particularly complex applications Since 1927 they have been part of our extensive range of reliable, highefficiency industrial motors for cement plants, pump systems, mines, the chemical, oil and gas industry, plant bution used for single drives or dampers and direct online motors in cases of replacement Cost effective reduction of harmonics using an active front end supply unit or at least a 12pulse line supply 2 Power demand in percent of airflow using a damper and a variable speed drive 120 100 80 60 40 20 0 Operating Range Fixed Speed Drive with Energy optimization in cement manufacturingCement Mixers Concrete Mixing Plants For Sale Hire Mixing cement takes highquality, specialised equipment that will accurately handle any variables Browse through our range of cement and mobile and fixed concrete plants for sale or hire and choose one that meets your requirements in size and featuresConcrete Mixers Supplier Plant Perth Cement

ACC Cement Plant, Locations and Features of ACC Plant

All the ACC Cement Plants use the cutting edge technologies and services which in turn produce high quality cement brands Set up in the year 1936, ACC has always worked dedicatedly to produce some of the best brands of cement and its business strategy is based on providing the best of products to the changing consumer market in the country and the world A periodic article by Folkert Haag on the cement and concrete industry printed in the November, 2015 issue of International Cement Review Excitement around what has been coined “the Internet of Things” continues to grow as manufacturers, vendors, and customers begin to realize the substantial benefits of embedding sensors in everything What IoT and the Digital World Mean for the Cement Building a Stronger India Founded in 1919, the MP Birla Group is amongst the largest industrial houses in India The company leads the scene the in the cement industry with strong presence in northerm, central and eastern IndiaBirla Corporation

Cement Corporation of India limited (CCI) Plant

Some of the well known CCI Cement Plants are Rajban cement plant: The Rajban Cement Plant is situated around 60 kilometers from the city of Dehradun in the district of Sirmaur The plant uses the dry process of manufacturing and produces around 1, 98,000 MT of cement per yearCement industry is an intensive source of fuel consumption and greenhouse gases (GHGs) emissions This industry is responsible for 5% of GHGs emissions and is among the top industrial sources of carbon dioxide (CO 2) emissionsTherefore, CO 2 emissions reduction from cement production process has been always an appealing subject for researches in universities and industryChallenges against CO2 abatement strategies in Rotor connected resistors are mainly used for motor starting applications which require a highstarting torque, such as loaded belt conveyors in the mining industry By using external resistors, it is possible to shift the motor maximum (breakdown) torque up to a starting torque point for motors under heavy loads during startupMotor Starting Control Resistors Hilkar