Cone Crusher an overview ScienceDirect Topics

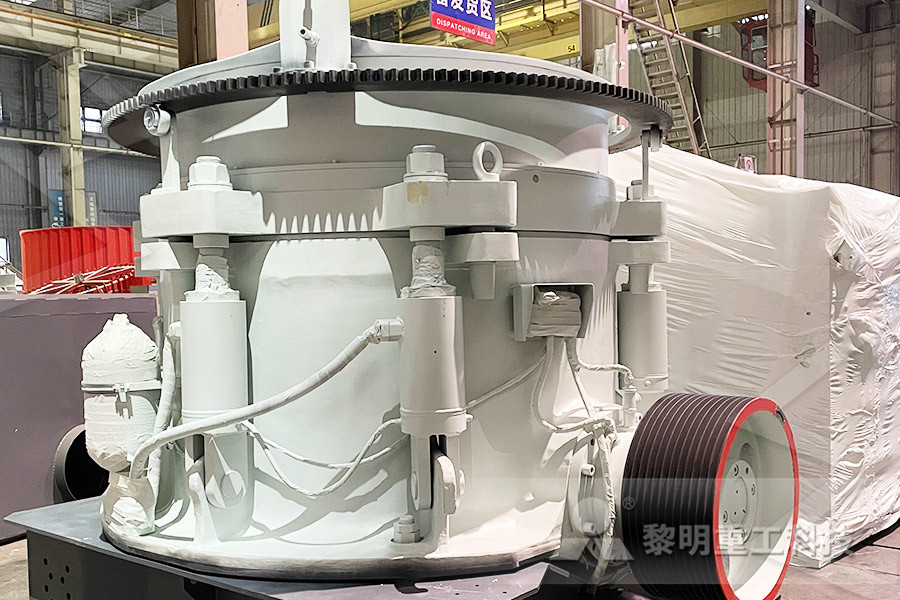

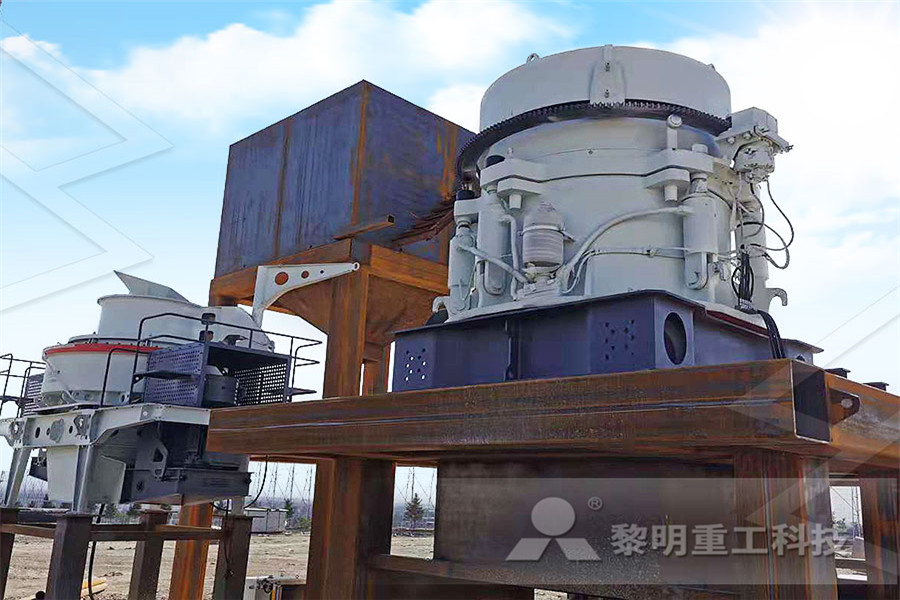

The cone crusher is a modified gyratory crusher The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 82) Power is transmitted from the source to the countershaft to a Vbelt or direct drive In this Cone Crusher article we want to educate you about what to consider when purchasing a cone crusher It also will inform and educate you if you are a current owner or operator of a Cone Crusher If you have a good base of knowledge about cone crushers you can skip through the article by choosing the topics belowWe will be exploring in more detail the following:Cone Crusher A Detailed Overview of Cone Crushers and What You 3 the experienced cone crusher operator will stop feeding before stopping the cone crusher This is because the stop crusher, when the machine is running slow, the added material and did not decrease, this will cause damage to the inside of the machine partsNecessary Knowledge of Cone Crusher Operation kara liu

Cone crusher basics in 4 minutes — SRP Sandvik

The Knowledge Hub Crushing Chambers Cone crusher basics in 4 minutes; The importance of the right mantle and concave What is the eccentric throw? What affects cone crusher performance? What affects liner life? Common Feed arrangement problems Optimal feed arrangement Premium Mantle Solutions – Flexifeed and Oversize BreakerThe preference of a company can be reflected by the quality of products/services it serves to clients For us, Maxwell Crushtech, our company's primary vision is to earn a prominent name in the industry through our innovative and modern products including 110KW Single Toggle Jaw Crusher, 37KW Single Toggle Jaw Crusher, 110KW Cone Crusher, etc, which are designed using advanced technologyCone Crusher2 天前 Cone Crushers The Symons Cone Crusher has come into almost universal use during the last few years for the final stage of crushing It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about 1½in size; but the main shaft of a cone crusher Cone Crushers for Sale 911 Metallurgist

The History of Jaw Crushers and Cone Crushers

The first cone crusher was developed by the Symons brothers to improve secondary and tertiary crushing applications While jaw crushers provide excellent primary crushing duties, new ways of crushing needed to be devised for finer and more consistently sized aggregates In 1920, the Symons brothers created the first cone crusher Cone Crusher also can use system of clears, make the arrange ore increase constantly, and then make the unusual matter out Under the function of the spring, the arrange ore mouth will reset automatically, the machine resumes normal The cone Discussion on Types of Cone Crushercnm2386的博客 Since the development initial stage of compound cone crusher ,they received widespread attention for its original characteristics, our company use the advanced technology to innovate and improve it, to have a material crushing force larger, high handlingThe Application Field of Compound Cone Crusherahhli4007

Advantages and Disadvantages of Cone Crusher

Knowledge Home > Knowledge > Content Advantages and Disadvantages of Cone Crusher Oct 12, 2017 Cone crusher with crushing force, high efficiency, high capacity, low cost, easy adjustment, the use of economic and other characteristics As the parts selection and structural design is reasonable, so long life, and broken product size uniformity Cone crusher, being used to crush hard materials, was designed by the American Simmons Brothers in 1920With nearly 100 years of development, it has become an indispensable role in the line of various mediumhard materials crushing and metal raw ore beneficiation It is estimated that about 56 billion tons of raw ore need to be crushed and ground each yearHow Does the Cone Crusher Develop? Fote Cone crushers are critical pieces for aggregate production, mineral processing operations, and recycling applications They’re typically a secondary or tertiary rock crusher and produce a fine or mediumsized aggregate material Since cone crushers have a large feed opening and small discharge sizes, this type of aggregate equipment has a high crushing ratio, making them quite efficient on Aggregate Equipment Review – Cone Crushers: Direct

introduces ® HP900 cone crusher for

The crusher is equipped with 's IC70C automation system to ensure optimum operating parameters enabling the full potential The IC70C is designed to be easy and simple to use All information can be tracked using a single screen and features help and troubleshooting options Find out more about ® HP900 Series cone crusher on A tremendous amount of material is crushed yearly by cone crushers Despite this fact, the detailed knowledge of how a cone crusher works from a process point of view is quite poor In order to achieve significant advances in crushing efficiency, increased knowledge is needed High quality knowledge can only be gained through fundamental CONE Chalmers Publication Library (CPL) Trio ® TC: When to use our live shaft cone crusher Trio ® TC series cone crushers have a live, moving shaft that rotates eccentrically with the head In the Trio ® TC cone crusher, both the shaft and head are moved in unison eccentrically during operation This proven design can be traced back to the original cone crushers invented in the Trio® cone crushers The Weir Group

MOBILE CONE CRUSHERS MOBICONE EVO Wirtgen Group

01 Cone crusher with a large stroke The MCO EVO crusher units have a threearm design and have a large stroke for high crushing capacities Thanks to their stable design and high crusher drive power, a high crushing ratio is possible Result: high throughput combined with The two main crushing parts of cone crusher are the mantle and the concave The axis of the mantle intersects the axis of the crushing chamber at point O, which is a pivot pointThe angle between the two axes is γ, which is an eccentric angle, as shown in Fig 1As the crusher is working, the mantle moves around the axis of the crushing chamberCone crusher chamber optimization using multiple A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Infogalactic: the planetary knowledge core

Discussion on Types of Cone Crushercnm2386的博客

Cone Crusher also can use system of clears, make the arrange ore increase constantly, and then make the unusual matter out Under the function of the spring, the arrange ore mouth will reset automatically, the machine resumes normal The cone The preference of a company can be reflected by the quality of products/services it serves to clients For us, Maxwell Crushtech, our company's primary vision is to earn a prominent name in the industry through our innovative and modern products including 110KW Single Toggle Jaw Crusher, 37KW Single Toggle Jaw Crusher, 110KW Cone Crusher, etc, which are designed using advanced technologyCone Crusher A tremendous amount of material is crushed yearly by cone crushers Despite this fact, the detailed knowledge of how a cone crusher works from a process point of view is quite poor In order to achieve significant advances in crushing efficiency, increased knowledge is needed High quality knowledge can only be gained through fundamental CONE Chalmers Publication Library (CPL)

Sandvik CH430 Cone crusher – Aggregate Equipment

Our knowledge and experience of cone crushing technology is based on years in the field The CH430 Stationary Cone crusher is designed to meet the needs of modern day crushing, and its excellent versatility and adjustable throw, give you the possibility to fine tune the outcome, therefore boosting your operation’s performance Trio ® TC: When to use our live shaft cone crusher Trio ® TC series cone crushers have a live, moving shaft that rotates eccentrically with the head In the Trio ® TC cone crusher, both the shaft and head are moved in unison eccentrically during operation This proven design can be traced back to the original cone crushers invented in the Trio® cone crushers The Weir Group 01 Cone crusher with a large stroke The MCO EVO crusher units have a threearm design and have a large stroke for high crushing capacities Thanks to their stable design and high crusher drive power, a high crushing ratio is possible Result: high throughput combined with MOBILE CONE CRUSHERS MOBICONE EVO Wirtgen Group

Comparative advantages and disadvantages of cone

Cone Crusher is widely used range, high efficiency crusher, cone crusher according to the scope of use, crushed into coarse, medium and fine crushing three pieces on the current situation of China crushed ore concentrator plant of view, broken equipment powered by the standard type cone crusher, crushing equipment uses a short head type cone crusher, has almost finalized The two main crushing parts of cone crusher are the mantle and the concave The axis of the mantle intersects the axis of the crushing chamber at point O, which is a pivot pointThe angle between the two axes is γ, which is an eccentric angle, as shown in Fig 1As the crusher is working, the mantle moves around the axis of the crushing chamberCone crusher chamber optimization using multiple The difference in the crushing stage is defined by the final product This means: the secondary application with the cone crusher can be defined roughly based on the final products of 25–80 mm The tertiary application roughly includes all final products lt;25 mmTools for the MOBICONE cone crusher PM

Comparison Of Cone Crushers From Cone Vs

Impact Crusher Vs Cone Crusher X Vs Y Aug 05 2014 the cone crusher crush the materials by pressing the materials between two walls with low operating and maintenance costs the cone crusher is a ideal choice when choosing between impact or cone crusher lastly the cone crusher provides highquality final products with desired size within a reduced cycle load impact crusher Cone Crusher also can use system of clears, make the arrange ore increase constantly, and then make the unusual matter out Under the function of the spring, the arrange ore mouth will reset automatically, the machine resumes normal The cone Discussion on Types of Cone Crushercnm2386的博客