Characterization and modelling of the grinding

On the contrary, there are only few investigations on the grindability of metal matrix composites, most of them concerning the role of reinforcement and the influence of grinding wheel abrasive on the process , , , , Since grinding is a complex manufacturing process with a lot of quantities which influence each other, modelling can be a Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESS Donuts The parameters to control in order to ensure a process under control are: dimensions and geometry of the part, deviations from the process, the tool wear, speed of cut, time's cycle, etc Ensuring The step in the process of grinding MetalWorking

Metal Grinding: Different Types of Metal Particles

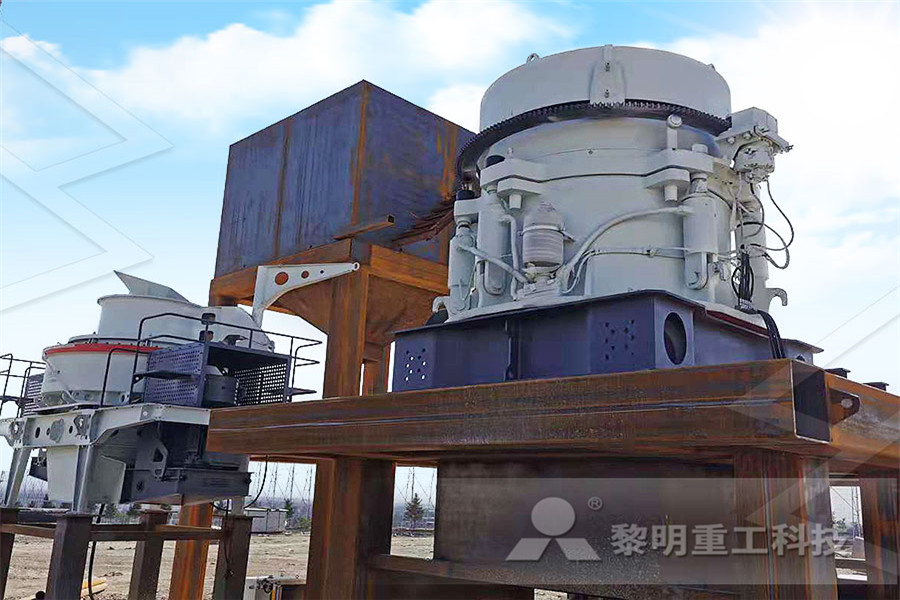

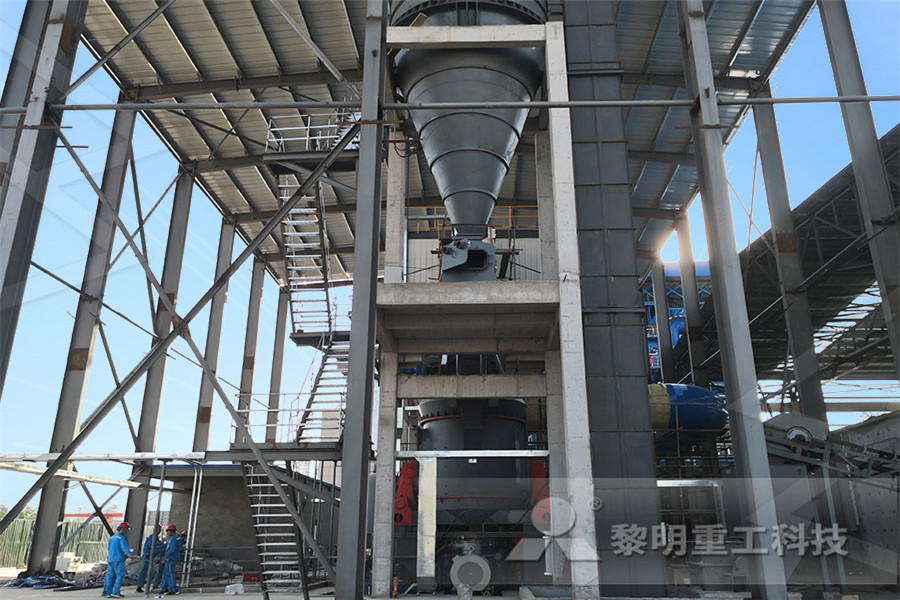

What is Metal Grinding? Metal grinding is a process used to smoothen and finish of metal parts, most often used for finishing edges, deburring, smoothening welding joints, creating a sharp edge, and for certain custom edge finishes The different types of grinders used in metal grinding are: Belt grinder: Uses a belt with an abrasive coating to The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing Crushing and Grinding Process JXSC Machine Grinding is a subset of cutting, as grinding is a true metalcutting process Grinding is very common in mineral processing plants and the cement industry Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimensionWhat is Grinding? Definition from Corrosionpedia

BASIC PRINCIPLE OF GRINDING Mechanical

2 天前 Grinding is the most common type of material cutting and surface generation process Mostly grinding process is used to shape and to provide better finishing parts of metals Grinding process uses one abrasive tool to make controlled contact with workpiece surface Normally grinding wheel is used as abrasive tool in process of grinding Inside diameter grinding, also called as internal grinding, is used for grinding the inner diameter of tubular object Workpiece or object will have already drilled hole and internal grinding process will be performed to finish the inner surface of workpiece with the help of small grinding TYPES OF GRINDING PROCESS Mechanical MODE OF METAL REMOVAL IN GRINDING PROCESS 309 microcutting, under slightly unfavourable conditions ploughing could easily predo minate resulting in inefficient metal removal (iv) Effect of impact speed on the T/N ratio The T/N ratio is seen to increase significantly with increasing speed for the pyramidal tool, but to decrease slightly in the An investigation into the mode of metal removal in

4 Ways to Grind Metal wikiHow

Grinding metal is a necessary process if you don’t want any sharp edges along a weld line or if you want to polish your piece As long as you have experience with power tools and a shop to work in, you can grind metal yourself With an angle grinder and a few different discs, you can smooth your edges and make the metal shine! Grinding Process: Mechanism of Grinding: In the grinding process, a layer of abrasive is responsible for removing the material from the work piece As machining starts, the abrasives of grinding wheel and work piece comes into contact and due to the rubbing force the initial layer from the grinding wheel is worn out and a fresh layer of the Grinding Machining Process : Complete Notes Guide to Blanchard and Precision Grinding Process The precision grinding process is very important to our machined industry like machinery, aerospace, medical and moreWhen seeking out a suitable metal machined workshop, it is best that you first understand the type of services availableGuide to Blanchard and Precision Grinding Process

Decisive metal grinding process for Industrial Uses

Avail offers on potent and conducive metal grinding process for various uses such as cutting, spinning, shaping etc at Alibaba Explore handy and useful metal grinding process now The parameters to control in order to ensure a process under control are: dimensions and geometry of the part, deviations from the process, the tool wear, speed of cut, time's cycle, etc Ensuring The step in the process of grinding MetalWorking The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as high as 50%Crushing and Grinding Process JXSC Machine

Metal Grinding Services Blanchard / Double Disc

Our metal grinding services provide a flat, stressfree part, ready for final machining Learn More DoubleDisc Grinding Grinding two sides of the part at the same time reduces costs by 50% and produces superior dimensional tolerances, parallelism and flatness to +/0002” with a surface finish of 16Ra on aluminum and 8Ra on ferrous alloys Diamond grinding wheels can also be metal bonded The various bonding agents give the wheels different grinding properties, as well as different properties with regard to safety Abrasive and polishing belts and discs are composed of a flexible base of paper or fabric to which the abrasive is bonded by means of a natural or synthetic adhesiveGrinding and Polishing ILO Encyclopaedia Chapter 4 Grinding, Reaming, Broaching Lapping In the republic of mediocrity, genius is dangerous —Robert G Ingersoll Introduction Although grinding, reaming, broaching, and lapping remove a relatively small metal volume compared with turning and milling, they are important processes because they are often the last machining operation and determine final size and finishChapter 4: Grinding, Reaming, Broaching Lapping

THERMAL DAMAGE IN GRINDING ABRASIVE

In some grinding applications, the use of an oil is impractical and a waterbased fluid must be chosen when this is the case, other measures can be taken to reduce the likelihood of thermal damage The temperature of the grinding fluid, for example, has a pronounced influence on its heat removal capability Salmon (1979) has shown that as the Grinding metal is a necessary process if you don’t want any sharp edges along a weld line or if you want to polish your piece As long as you have experience with power tools and a shop to work in, you can grind metal yourself With an angle grinder and a few different discs, you can smooth your edges and make the metal shine! 4 Ways to Grind Metal wikiHow Grinding Process: Mechanism of Grinding: In the grinding process, a layer of abrasive is responsible for removing the material from the work piece As machining starts, the abrasives of grinding wheel and work piece comes into contact and due to the rubbing force the initial layer from the grinding wheel is worn out and a fresh layer of the Grinding Machining Process : Complete Notes mech4study

Grinding Process, Finish Machining, Aerospace Parts

Utilizing the VIPER grinding process, manufacturers achieve metal removal rates up to 5times greater than they achieved with traditional creep feed grinding As it was initially developed, VIPER was intended as an intermittent dress grinding process Recently, this process was enhanced further by utilizing a continuous dress of the grinding Grinding is machining process that’s used to remove material from a workpiece via a grinding wheel As the grinding wheel turns, it cuts material off the workpiece while creating a smooth surface texture in the process While grinding sounds simple enough, there are probably some things you don’t know about this machining process5 Facts About Grinding Processes Monroe EngineeringAlibaba offers 1,684 metal process grinding machine products About 1% of these are Grinding Equipment, 0% are Mine Mill, and 0% are Flour Mill A wide variety of metal process grinding machine options are available to you, such as warranty of core components, key metal process grinding machine, metal process grinding

Automating the moldmaterial grinding process — Shibaura

In this paper, we report the application of the technique to an ordinary grinding wheel, and our attempt to automate the grinding work of STAVAX and SKD11 metal materials AB Grinding is difficult to control because abrasive grains are scattered randomly on the surface of the grinding wheel, and the quality of the grinding work is strongly Grinding; Machining is one bulk material removal process (ie high MRR) Thus it is economical and suitable to give proper size and also for semifinishing Grinding has low material removal rate and is preferred only for finishing Accuracy and tolerance achieved by conventional machining operations are not so goodDifference Between Machining and GrindingA new development of hybrid inprocess electrical dressing of metalbonded diamond grinding wheels is proposed in this paper The electrical dressing method is used for overcoming the limitations of the conventional dressing methods available in relation to a superabrasive wheel because of the hardness of its abrasive grains and the durability of its bonding material[PDF] InProcess Electrical Dressing of MetalBonded

THERMAL DAMAGE IN GRINDING ABRASIVE ENGINEERING

In some grinding applications, the use of an oil is impractical and a waterbased fluid must be chosen when this is the case, other measures can be taken to reduce the likelihood of thermal damage The temperature of the grinding fluid, for example, has a pronounced influence on its heat removal capability Salmon (1979) has shown that as the The purpose of atypical grinding processes is to obtain fine metal powders of extremely high specific surface which should be evaluated by the parameter of hiding power ability of pigment materials This paper shows the development of this basic parameter of metal pigment products under the wet process of milling using a pilotplant ball mill Hiding Power of Aluminum Metal Pigments Development in