Maintenance of Double Roller Crusher Luoyang Dahua

The maintenance of double roller crusher should be taken from the feeding material, safety adjustment, center line, finished granularity and so onThe rule of thumb for the Double Roll Crusher’s ratio of reduction is 4:1 The simplified design gives these units excellent reliability and requires very little maintenance The crushers are designed with builtin tramp relief that allows for the passing of Double Roll Crushers McLanahanSo thedaily maintenance of roll crusher is very important Here is some points of what we need to payattention to in the daily production: 1 Roller clearancedecide crushing strength, keep the clearance in the appropriate range Adjustthe spring pressure, maintain parallel double roller to prevent skewedDaily Maintenance of Roll Crusher

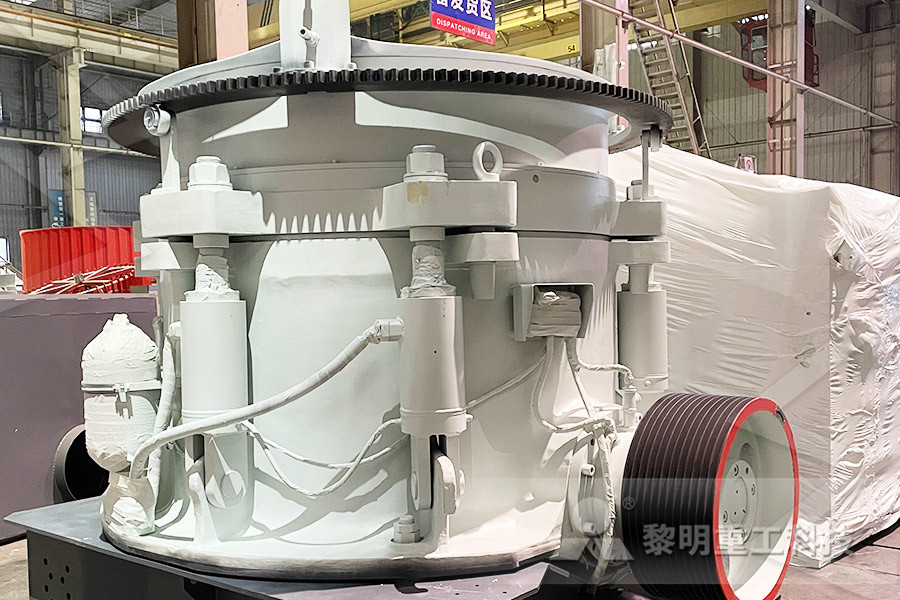

2PG SERIES DOUBLE ROLLER CRUSHER

order to facilitate maintenance, the crushing roll shafts are arranged in heavyduty cast steel housings with lubricated, amply dimensioned spherical roller bearings Materials used are of highly wearresistant specially cast alloys in order to achieve long lifetimes of parts MAIN CUSTOMER BENEFITS OF DOUBLE ROLLER CRUSHER DOUBLE ROLL SPECIFICATIONS Sectional drawing of Double Roll Crusher fitted with smooth rolls Capacities, dimensions and weights will vary with the characteristics of each individual material The details contained within this leaflet are for information purposes only and we reserve the right to change product specifications without prior noticeDOUBLE ROLL CRUSHERS Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attritionConstruction, Working and Maintenance of Crushers for

Features Roll Crushers TerraSource

accessibility to rolls for maintenance from front or back of crusher 1 Model 3060D, TwoStage, FourRoll Crusher 7 Gearboxes–uniform sizing requires the positive timing of crusher rolls provided by Gundlach’s patented gearboxes These units maintain constant relationship of oneRoll crushers are often fed by apron feeders that direct feed material between a fixed and a moveable roll The two crusher rolls, equipped with crushing segments, rotate inward and crush oversized material, while fine material passes the crusher without additional crushingRoll Crushers TAKRAF GmbH A double toothed crusher with less volume is composed of two toothed rollers which is installed in parallel and rotates in opposite directions The twotoothed rollers adopt nonmeshing and nonconstant speed operation to strengthen the degree of occlusion, which ideally prevents the material from slipping thus improving the crushing Reliable Toothed Roll Crusher Fote Machinery(FTM)

Roll Crusher With stable Performance Fote

With the supporting CPU, operators can control roll crushing machines and monitor gaps between rollers, and clean up the crushing cavity through the central control room, which will help save energy of 30% to 50% Dustproof device in roll crushersMaintenance Of Double Roll Crusher For Coal Humboldt Wedag Inquiry Online Double Roller Crusher Henan Deya Machinery Co Ltd Double roller crusher introductiondouble roll crusheris reliable in operation simple inmaintenance low in running cost and discharge size can be adjusted it is widely used in the processing of brittle materials and tough Roller Crusher Maintenance Of Double Roll Crusher For Coal DoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie lignite and mineral coal, clay, marl, limestone and similar raw materials as well as for overburden and ores Sticky and soft materials are reliably crushed in Doublerollcrushers manufactor thyssenkrupp

Double Roller Crusher JXSC Machine

Double roll crusher is the most used type We produce industrial roller crushers and laboratory uses small roll crusher 【Advantages】 Replacement wearresistant lining, long service life, convenient maintenance Compact structure, lightweight, small size, for the same production capacity requirements of the crushing system, equipped with The maintenance of the machine should be paid great attention to when it is used If the double roll crusher regularly check the connection of each component, when there is loose should be timely Stop and tighten 3 Double roll crusher bearings are strictly prohibited to work for a long time without lubricating oil to avoid bearing damage Points For Attention When Using Double Roll Crusher News LC14 Marcy® Double Roll Crusher features 9x12in (229x305mm), DiaxW heavy 304 stainless steel crushing rolls with Nihard roll facings The unit features a Vbelt drive, with a 5hp TEFC motor that produces uniform speed throughout the crushing processDouble Roll Crusher, 13mm Particle Size Gilson Co

Features Roll Crushers TerraSource

accessibility to rolls for maintenance from front or back of crusher 1 Model 3060D, TwoStage, FourRoll Crusher 7 Gearboxes–uniform sizing requires the positive timing of crusher rolls provided by Gundlach’s patented gearboxes These units maintain constant relationship of one Double Toothed Roll Crusher Applied material: coal, pebble, perlite, limestone, dolomite, etc Its outstanding features: high crushing capacity, hadraulic pressure used to adjust the distance between the rollers, and the centralization lubrication on the brearingReliable Toothed Roll Crusher Fote Machinery(FTM)Advantages of Smooth Double Roll Crusher As the material is crushed only once, when it passes through the gap, the percentages of fines is much less As there is no to fro movement, but a fixed gap, percentage of oversize is bare minimum, that too, only in two dimensions one dimension is always less than gap settingSmooth Double Roll Crusher Manufacturer,Smooth Double Roll

Mobile Mining Crusher Product Overview

Double Roll Crusher • Has a modular design with an easy access for maintenances • Wheel mounted roll out for quick shaft/teeth replacements • Design accommodates properties of the material ie abrasiveness, stickiness • Equipped with dual VFD control reversible drives Capacity Nominal 9K MT/h 10K ST/h Maximum 108K MT/h 12K ST/h Purchasing equipment: 2PG1560 roll crusher, YK vibrating screen, sand washing machine, etc The roll crusher produced by Fote has fine finished products and the best effect on sand making for river pebble Due to its good finished product size, low powder content and low price, it is widely favored by Indonesian customersRoll Crusher With stable Performance Fote Machinery(FTM)China the double roll crusher maintenance and security technology find detail roll crusher, double roll crusher from henan Entered incorrect captcha China The Double Roll Crusher Maintenance And

Roller Crusher Maintenance Of Double Roll Crusher

Maintenance Of Double Roll Crusher For Coal Humboldt Wedag Inquiry Online Double Roller Crusher Henan Deya Machinery Co Ltd Double roller crusher introductiondouble roll crusheris reliable in operation simple inmaintenance low in running cost and discharge size can be adjusted it is widely used in the processing of brittle materials and tough DoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie lignite and mineral coal, clay, marl, limestone and similar raw materials as well as for overburden and ores Sticky and soft materials are reliably crushed in Doublerollcrushers manufactor thyssenkrupp Double Toothed Roll Crusher Applied material: coal, pebble, perlite, limestone, dolomite, etc Its outstanding features: high crushing capacity, hadraulic pressure used to adjust the distance between the rollers, and the centralization lubrication on the brearingReliable Toothed Roll Crusher Fote Machinery(FTM)

Roll Crushers TAKRAF GmbH

Roll crushers are often fed by apron feeders that direct feed material between a fixed and a moveable roll The two crusher rolls, equipped with crushing segments, rotate inward and crush oversized material, while fine material passes the crusher without additional crushing Double Roll Crusher • Has a modular design with an easy access for maintenances • Wheel mounted roll out for quick shaft/teeth replacements • Design accommodates properties of the material ie abrasiveness, stickiness • Equipped with dual VFD control reversible drives Capacity Nominal 9K MT/h 10K ST/h Maximum 108K MT/h 12K ST/hMobile Mining Crusher Product OverviewAdvantages of Smooth Double Roll Crusher As the material is crushed only once, when it passes through the gap, the percentages of fines is much less As there is no to fro movement, but a fixed gap, percentage of oversize is bare minimum, that too, only in two dimensions one dimension is always less than gap settingSmooth Double Roll Crusher Manufacturer,Smooth

Features Roll Crushers TerraSource

accessibility to rolls for maintenance from front or back of crusher 1 Model 3060D, TwoStage, FourRoll Crusher 7 Gearboxes–uniform sizing requires the positive timing of crusher rolls provided by Gundlach’s patented gearboxes These units maintain constant relationship of one Purchasing equipment: 2PG1560 roll crusher, YK vibrating screen, sand washing machine, etc The roll crusher produced by Fote has fine finished products and the best effect on sand making for river pebble Due to its good finished product size, low powder content and low price, it is widely favored by Indonesian customersRoll Crusher With stable Performance Fote CPC Smooth Roll Crusher Application Comminution of hard and mediumhard material (lime stone, magnesia, salt, fertilizer, coke etc) Throughput up to 500 mt/hr, depending on Smooth Roll Crusher – CPC GmbH – Crushing