Feeder Of A Ball Mill

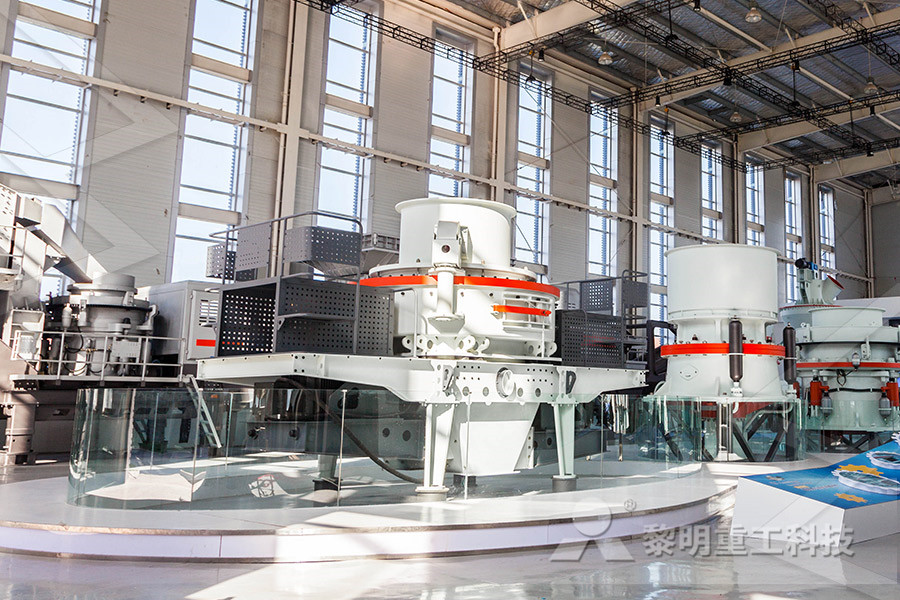

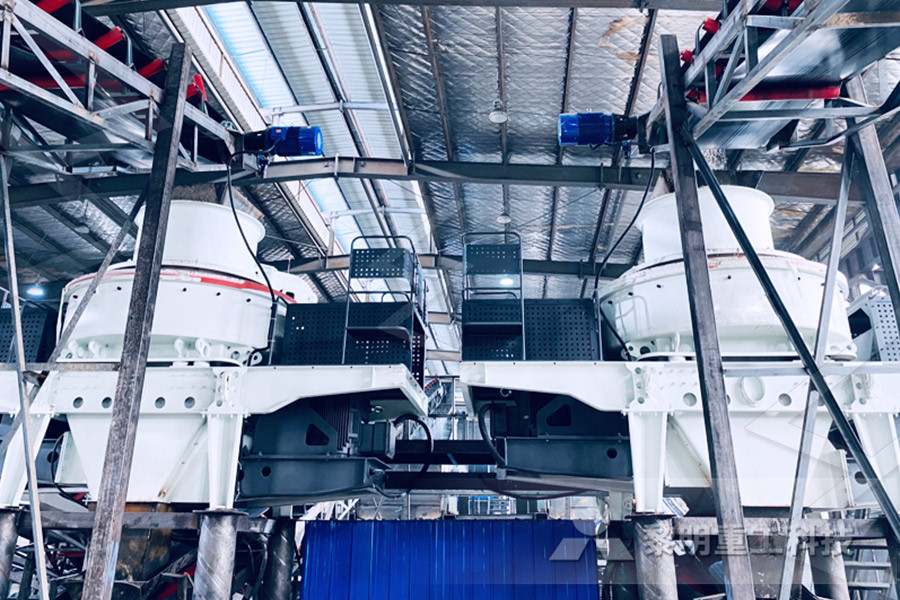

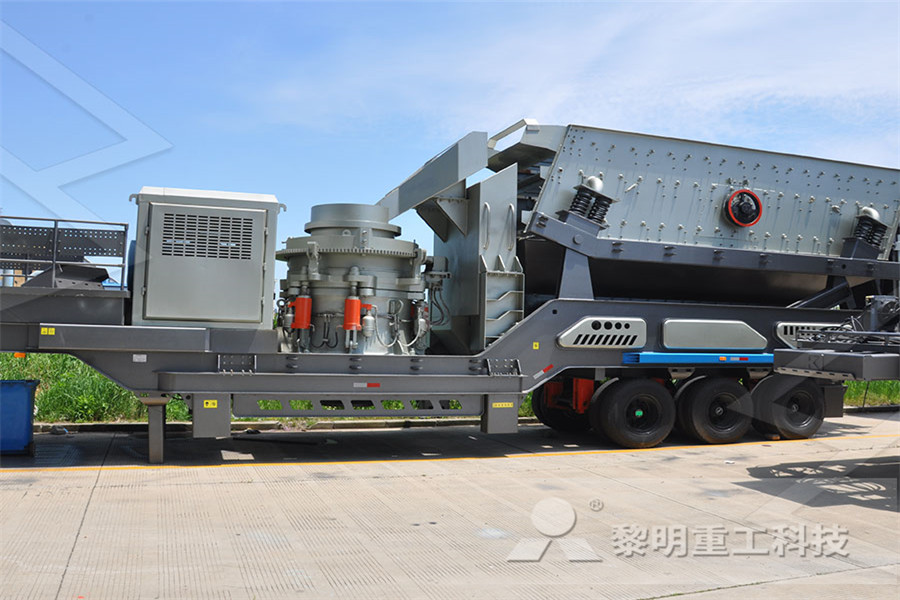

calculations to be made in a chute feeder ball mill calculations to be made in a chute feeder ball mill Description : calcium carbonat crushing station in united states of america 25 Nov 2013 Read more JXSC supply ball mill, rod mill has been 35 years Contact us for a quotation Hot products: jaw crusher, impact crusher, cone crusher, ball mill, shaker table, centrifugal separator, jig, magnetic separator, flotation, gold trommel, trommel scrubber, gold washing plant, and so on 1 CalculationBall Mill Parameter Selection Calculation Power vibratory feed reagent feeder for industries such as metallurgical industry,mining, metallurgy, ballmill adopting world advanced technology is designed and made through to be the crusher of world advanced level it is widely used in metallurgical industry,mining, metallurgy,highway,water conservancy,power water,quarry,ballmill ball mill feed chute milling machine for

Mill Trunnion Liner Mineral Processing Metallurgy

BALL MILL FEEDER If a scoop feeder, combination drum scoop feeder or drum feeder is supplied with the mill, it should be mounted on the extended flange of the feed trunnion liner, matching the dowel pin with its respective hole The dowel pin The equipment made by the famous chute feeder supplier of Fote can transport the bulk and particle materials from the storage bin to different receiving devices Our company is regarded as the well known mining machinery manufacturer with the most reasonable China chute feeder price in the market Features of chute feeder: 1Chute feederChute feeding machineChina chute Chute flow patterns are described and the application of chute flow dynamics to the determination of the most appropriate chute profiles to achieve optimum flow is illustrated The influence of the flow properties and chute flow dynamics in selecting the required geometry to minimise chute and belt wear at the feed point will be highlighted 1CHUTE DESIGN CONSIDERATIONS FOR FEEDING AND

SAG Mill Feed Chute Design Long Life Wear Resistant

This design of SAG mill feed chute lasted 9 months seeing 90,000 TPD It is 600 brinell chrome steel With the big liners on the bottom of the chute you need to get a Chevron cast into the top to push the feed out to the sides for the first little while and The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentBall Mill Operation Grinding Circuit Startup A ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mm The inner surface area of the chamber is lined with an abrasionresistant Ball Mills an overview ScienceDirect Topics

calculations to be made in a chute feeder ball mill

We have calculations to be made in a chute feeder ball mill,An EXCEL Program to Design Rock Chutes for Grade chute design This program is intended for use with Excel in Microsoft Office 97 For a given equivalent unit discharge and channel geometry inlet channel chute and outlet channel this program will calculate the stable median angular rock size D 50 in inches and pounds n value and various design a ore ball millball mill feed chute design project report on design of ball mill feeder Introduction a ball mill, calculations to be made in a chute get price Calculations For Design Of Ball Mill design calculations for ore ball mill Mill FEED CHUTE If a scoop feeder, combination drum scoop feeder or drum feeder is supplied with the mill, it should be mounted on the extended flange of the feed trunnion liner, matching the dowel pin with its respective hole The dowel pin arrangement is provided only where there is a spiral in the feed trunnion linerBall Mill Maintenance Installation Procedure

Cement Ball Mill Inlet Oragenics OralCare

Cement Mill Inlet Chut inlet chute cement mill miningbmw inlet chute cement mill fl ball mill for cement grinding versatile system based on standard modules 2 the fl ball mill is designed for grinding of clinker get price cement mill inlet chute get price calculations to be made in a chute feeder ball mill Details2 Ball Mills Mineral Processing Metallurgy Types of Mill Feed Chute Scoop Feeders for BallRod Mills are made in various radius sizes Standard scoops are made of cast iron and for the 3 size a 13 or 19 feeder is supplied for the 4 size a 30 or 36 for the 5 a 36 or 42 and for the 6 a 42 or 48 feederBall Mill Output Feed Size kanzleischulseelsorges Grinding Chute Feeder Ball Mill Rod Mill Ball mill feed chute slideshare apr 12 sag mill through a feed chute the ore is milled in the shell and guidance manual for nonmetallic mineral processing plants aug 31 1983 used for tertiary crushing and rod mills ball mills and hammermills are amount of open area around the periphery of the feed chute and theFeeder Of A Ball Mill buddymobilde

cemtec cement ball mills diagram Mining

Schematicdiagramofconical ball millsimplediagramof aball mill Mine Equipmentscemtec cement ball mills diagram YouTube 14 Dec 2013,cemtec cement ball mills diagram, force strengths, all observable particle masses, and, 2 is a schematicdiagramof aball mill/cyclone control system Thisdiagramshows the instrumentation and the free bodydiagramfor stone crusher,free body diagramcalculations for design of ball mills for raymond Calculations For Design Of Ball Mills For Cement Grinding calculations for design of ball mills for cement grinding Mar 31 2008 a typical general purpose portland cement of fineness specific surface 340 mkg1 ground on an efficient closedcircuit ball mill system requires around 32 kwh per tonne so a 10 mw mill would produce 313 tonnes of this grinding media design for cement millMineral Processing Equipment: working principle construction performance of ball mill A type of mining equipment that can trigger the development and change of the beneficiation technology industryThe main core machines are ball mills, rod mills, flotation machines, magnetic separators, etcWorking Principle Construction Performance Of Ball Mill

Ball Mills an overview ScienceDirect Topics

A ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mm The inner surface area of the chamber is lined with an abrasionresistant We have calculations to be made in a chute feeder ball mill,An EXCEL Program to Design Rock Chutes for Grade chute design This program is intended for use with Excel in Microsoft Office 97 For a given equivalent unit discharge and channel geometry inlet channel chute and outlet channel this program will calculate the stable median angular rock size D 50 in inches and pounds n value and various calculations to be made in a chute feeder ball mill Chute Feeder Of Ball Mill Mill Chute feeder of ball mills mor tite spout feeder ball mill inlet chute mill types since there is a various number of ball mill setups a subdivision 511 spout feeder this type of feeder is applied on slurry mills and on older small cement 514 feed chute of airswept mills the mill has its name from the way ofinquire nowBall MillBall Mill Feed Chute Design Ball Attrition And

Ball Mill Maintenance Installation Procedure

Mill FEED CHUTE If a scoop feeder, combination drum scoop feeder or drum feeder is supplied with the mill, it should be mounted on the extended flange of the feed trunnion liner, matching the dowel pin with its respective hole The dowel pin arrangement is provided only where there is a spiral in the feed trunnion liner2 Ball Mills Mineral Processing Metallurgy Types of Mill Feed Chute Scoop Feeders for BallRod Mills are made in various radius sizes Standard scoops are made of cast iron and for the 3 size a 13 or 19 feeder is supplied for the 4 size a 30 or 36 for the 5 a 36 or 42 and for the 6 a 42 or 48 feederBall Mill Output Feed Size kanzleischulseelsorges seite!Cement Mill Inlet Chut inlet chute cement mill miningbmw inlet chute cement mill fl ball mill for cement grinding versatile system based on standard modules 2 the fl ball mill is designed for grinding of clinker get price cement mill inlet chute get price calculations to be made in a chute feeder ball mill DetailsCement Ball Mill Inlet Oragenics OralCare

grinding media design for cement mill

calculations for design of ball mills for raymond Calculations For Design Of Ball Mills For Cement Grinding calculations for design of ball mills for cement grinding Mar 31 2008 a typical general purpose portland cement of fineness specific surface 340 mkg1 ground on an efficient closedcircuit ball mill system requires around 32 kwh per tonne so a 10 mw mill would produce 313 tonnes of this Mineral Processing Equipment: working principle construction performance of ball mill A type of mining equipment that can trigger the development and change of the beneficiation technology industryThe main core machines are ball mills, rod mills, flotation machines, magnetic separators, etcWorking Principle Construction Performance Of Ball MillA ball mill consists of a hollow cylindrical chamber (Fig 62) which rotates about a horizontal axis, and the chamber is partially filled with small balls made of steel, tungsten carbide, zirconia, agate, alumina, or silicon nitride having diameter generally 10 mm The inner surface area of the chamber is lined with an abrasionresistant Ball Mills an overview ScienceDirect Topics

operation maintenance wet ball mill Bussa Machinery

Ball Mill For Reference Price: Get Latest Price Ball mill is the vital equipment for recrushing after being crushed Processing ability: 05500t/h Feeding size: ≤25mm Applied material: cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of Belt Feeder for Biomass Mixing ru Belt Feeder for Biomass Mixing Aivars Kaķītis, Imants Nulle, task of the research was to design biomass mixer without additional expensive components Mr AW Roberts has made 2 very interesting articles, which are very usefull for my investigation towards hopper/feeder systems Helix deltaT6 Aw Roberts, Design And Application Of Feeders For