what is vertical roller mill in cement factory

vertical cement grinding mill from 1020 t h vertical cement grinding mill from 10 20 t h Vertical roller mill Vertical grinding mill vertical roller ball mill grinding machines Ball Mill grinder for griding seeds made in USA Make a Ball Mill in 5 Minutes Instructables Wiki says "A ball mill is a A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true competitor and alternative for ball mill and has increased its market share in the cement mills in recent timesReview on vertical roller mill in cement industry its Generally speaking, ball mill is the most common powder grinding machine in the cement industry However, with the development of the social technology, vertical roller mill can replace ball mill, in some specific circumstances; especially when we want to process the powder below 1250 mesh, the vertical roller mill has absolute advantagesHRM Vertical Roller Mill in Cement IndustryHefei

vertical roller mill for cement factory process flow

vertical roller mill for cement factory process flow Operation material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the Taking grinding P o425 cement as an example, the pre grinding closedloop system composed of roller press or external circulation vertical mill and powder concentrator has a circulation load rate of 200% – 300%, and the specific surface area of the selected materials is 180280m 2 / kg The following table lists the main machine Cement Grinding Machine Selection: Vertical Roller cement in a vertical roller mill, the layout, as shown in Figure 7, is prepared with provisions for recirculation of hot mill exit gas to the mill inlet to maintain a proper , cement grinding 2 %Cement grinding Vertical roller mills versus ball mills

Vertical Cement Mill Great Wall

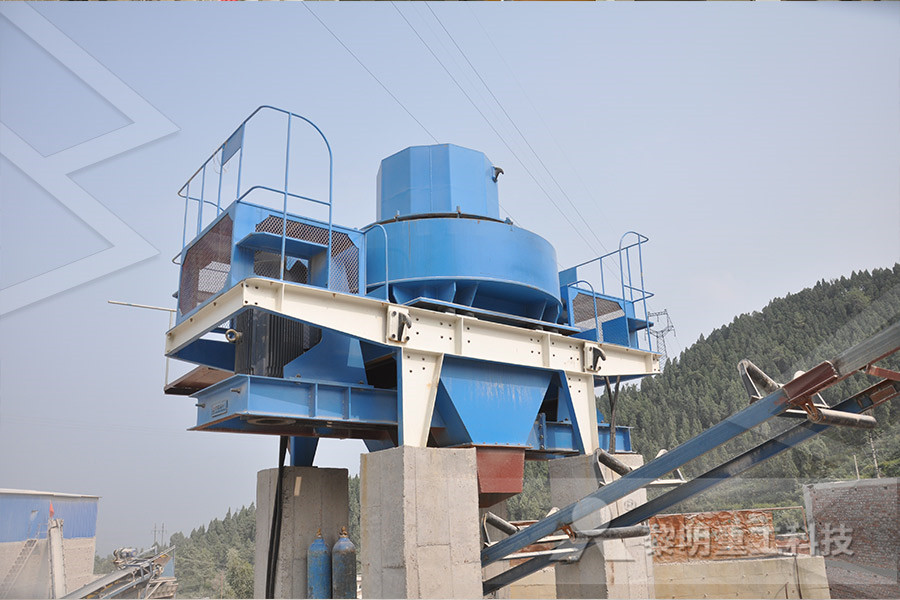

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement Ball Mills Or Vertical Roller Mills: Which Is Better For The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement Cement Roller Press Roller Press In Cement Plant

HRM Vertical Roller Mill in Cement IndustryHefei Zhongya

HRM Vertical Roller Mill in Cement Industry As we all know that the HRM vertical roller mill is one of very important powder making machines in the cement industry Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most suitable machine in cement industry The vertical roller mill (VRM) is a core equipment in the cement production process It can grind a broad range of materials, including cement raw materials, cement clinker, and granular blast furnace slag SINOMALY recommends suitable equipment based on the differences in the grindability and abrasiveness of the materialVertical Roller Mill Crushing Plant Equipment Provider Vertical Roller Mill In Cement Production Process At present, cement production process industry widely adopted vertical roller mill as a cement raw materials, improves the automation of cement production line, in the cement production process, not only solves the slag of the impact on the environment, but also provides a lot of cement to the market, to meet the social development demand for vertical roller mill for cement process

Vertical Roller Mill for Cement Raw Material SINOMALY

Vertical Roller Mill for Cement Raw Material SINOMALY produces cement raw material grinding mills in various specifications These machines are suitable for grinding mill production lines with an output of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d and 8000t/d Vertial roller mill is widely used in cement, power, metallurgy, chemical industry, nonmetallic mineralcement, coal, calcite, talc, iron ore, copper ore, graphite, quartz, slag etc Working principle Vertical rolling mill has two pairs of grinding rollers Each pair of roller is composed of two narrow rollers and mounted on the same axis and SRM vertical roller mill, vertical mill, coal mill, cement Cement vertical mill is used to grind cement raw materials Its working principle is: raw materials enter the discharge pipe through the threeway air lock valve, and the discharge pipe enters the inside of the mill through the side of the separatorCement vertical mill Factory, Suppliers China Cement

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated China Vertical Roller Mill supplier, Cement Mill, Roller Mill Manufacturers/ Suppliers Sunlike GroupChina Vertical Roller Mill manufacturer, Cement Mill Jiangsu Pengfei Group Co, Ltd is the national leading enterprise of building material industry, the manufacturing and exporting base for complete set of cement machinery equipment, the provincial abide by contracts and keep ones words enterprise Our company can take on the complete set of service such as manufacturing, installation, debugging, etc for the cement machinery, metallurgy Project / Vertical mill achievements cement machinery

Home Cemminerals NV

At the heart of our brandnew factory, built in 2018 next to deep water, is a stateoftheart vertical cement millOur VRM has a production capacity of 1 million tonnes per year making it the largest of its kind in Europe To feed this mill, we have a raw materials storage capacity of 200,000 tonnes as well as 10 silos with a capacity of 2,500 tonnes each for the finished product The vertical roller mill (VRM) is a core equipment in the cement production process It can grind a broad range of materials, including cement raw materials, cement clinker, and granular blast furnace slag SINOMALY recommends suitable equipment based on the differences in the grindability and abrasiveness of the materialVertical Roller Mill Crushing Plant Equipment Provider HRM Vertical Roller Mill in Cement Industry As we all know that the HRM vertical roller mill is one of very important powder making machines in the cement industry Because of the high efficient and high capacity the vertical roller mill, so use the vertical roller mill to process the cement raw powder is the most suitable machine in cement industryHRM Vertical Roller Mill in Cement IndustryHefei Zhongya

vertical roller mill for cement process

Vertical Roller Mill In Cement Production Process At present, cement production process industry widely adopted vertical roller mill as a cement raw materials, improves the automation of cement production line, in the cement production process, not only solves the slag of the impact on the environment, but also provides a lot of cement to the market, to meet the social development demand for The cement vertical roller mill equipment is used for maintenance and repair reasons, phenomena, required working hours, downtime, construction personnel and number of people, etc, and then statistical analysis, to determine the items to reduce maintenance operations, select the appropriate repair cycle and Check the cycle, select or revise the inspection items and inspection standards Cement vertical roller mill maintenance and maintenance cycle [Applicable Material]: Vertical roller mill integrates crushing, grinding, powder concerntration, drying and conveyoring It can be widely used in cement, power, metallurgy, chemical industry, nonmetallic mineral It is used to grind granular and powdered materials into powder with required finenessSRM vertical roller mill, vertical mill, coal mill, cement

Ball Mills Or Vertical Roller Mills: Which Is Better For

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated China vertical cement raw mill supplier, roller mill for cement grinding, clinker grinding mill, mill disc 13005600MM, 2 3 4 roller 11002500MMChina Vertical Roller Mill Manufacturer Supplier for LOESCHE Awarded Order for Cement Plant in Nepal LOESCHE has been able to convince the cement division of the Chaudhary Group (CG Group) of the advantages of its vertical roller mill technology LOESCHE has managed to gain a new customer in Nepal, namely the cement division of the Chaudhary Group based in KathmanduCoal Mills for Cement Plants Loesche

Ceramic embeded roller liner for vertical mill

Amincem and his expert team made a test in a cement plant in India We compared the wear of our ceramic rollers against competition roller on a vertical Roller Mill during 6000 hrs working time As presented here after, our rollers was more than 2 times better than the competition roller in wear Rotary Kiln, Kiln Tyre, Girth Gear Pinion for Kiln, Support Roller with Shaft Assembly for Kiln Horizontal Ball Mill, Mill Head/Ends, Trunnion, Girth Gear Pinion for Ball Mill and Bearings Base Vertical Roller Mills Foundation Frames, Internals Components Trial AssemblyThe KCP Limited Heavy Engineering Heavy Engineering