ilmenite mining process triathlonclubsurseech

Most ilmenite forms during the slow cooling of magma chambers and is concentrated through the process of magmatic segregation BARRAMBIE TITANIUM PROJECT ‐ UPDATE Ti‐V‐Fe mineralisation occurs as bands of cumulate aggregations of vanadiferous magnetite (martite)‐ilmenite (leucoxene) in massive and disseminatedWhile the mineral chemistry of ilmenite and titanomagnetite is well understood, the process of ore formation in LMI is still enigmatic The traditional view is that the minerals crystallize from their host magmas and settle (because of their high specific gravity) to the base of the magma chamberIlmenite an overview ScienceDirect TopicsHistorically the Company has mined between 25 and 27 million tonnes of ore annually with ore trucked to a Primary Beach and Secondary Concentrator Plant located directly adjacent to the mining areas Ore is processed via a Primary Beach Concentrator (“PBC”) where the minerals are separated by a chemical free gravity process before theilmenite mining process german ore crushing

Ilmenite – the primary source of titanium extraction by

Ilmenite – the primary source of titanium extraction by chlorine process Ilmenite is the most important ore of titanium mining with the chemical formula FETIO3 (iron, titanium and oxygen), named for its place of discovery at Ilmen Lake in the Ilmen Mountains, Ilmenite mining process Most ilmenite ore are poor ilmenite ore, so the ore processing must be carried out Ilmenite ore beneficiation methods currently used for the mechanical selection including washing, screening, reelection, high intensity magnetic separation and flotation, as well as fire enrichment, chemical processing methodthe by products when mining ilmeniteAIR has adopted a shallow panel strip mining technique to extract the ilmenite ore for processing according to the pit mining campaign sequence in Figure 22 The mine plan is intended to proceed in a north to south directionProject Introduction ilmeniteau

ECOFRIENDLY MINING PROPOSAL ILMENITE:

Ilmenite is the primary ore of titanium, along with rutile Most ilmenite forms during the slow cooling of magma chambers and is concentrated through the process of magmatic segregation A large underground magma chamber can take centuries to cool As it cools, crystals of ilmenite will form at a specific temperature Titanium is a rare metal that because of its dispersal and hard to extract Also a silverwhite transition metal Its features are lightweight, high strength, resistance wet chlorine corrosion Titanium is found in ore, such as Rutile and Ilmenite Extraction of titanium from ore is called the titanium mining processTitanium Mining Process Titanium Dioxide Mining ILMENITE (Iron Titanium Oxide) Amethyst Galleries It is these layers that constitute a rich ore body for titanium miners Placer deposits often contain both rutile and ilmenite and there are enough of these therefore ilmenite is a minor ore of iron as the magnetite and ilmenite are processed forIlmenite And Rutile Ores Mining And Processing

ilmenite mining process triathlonclubsurseech

mining machinery for magnesite ore mineral Categories Gold Flotation Production Line Manganese Ore Magnetic Separation Production Line Graphite Ore Beneficiation Process Gold Cil Processing Line Mining Placer mining Britannica Mining Placer mining Placers are unconsolidated deposits of detrital material containing valuable mineralsArrastras Historic Gold Mining Method for Processing Ore After running material for several weeks the grinding process would be stopped and the amalgam would be collected from the cracks in the bottom of the arrastra then it would be carefully panned and retorted to extract the goldilmenite mining process german ore crushing Ilmenite mining process Most ilmenite ore are poor ilmenite ore, so the ore processing must be carried out Ilmenite ore beneficiation methods currently used for the mechanical selection including washing, screening, reelection, high intensity magnetic separation and flotation, as well as fire enrichment, chemical processing methodthe by products when mining ilmenite

Ilmenite And Rutile Ores Mining And Processing

Ilmenite Processing Mining Process of applying for sand mining youtube oil sand is a mixture of bitumen, the reclamation process begins as soon as mining operations are completedlmenite sand mining process ilmenite ore mining process lmenite and rutile ores mining and processing cachedthe ilmenite ore processing22 jan 2014 the ilmenite ore processingRaw ore contains mud, 0400mm size The ilmenite processing plant usually goes through 4 stages: crushing, grinding, magnetic separation, and drying The equipment used in the process plant includes a jaw crusher, cone crusher, ball mill, magnetic separator, spiral classifier, dryer, etcAustralia 250TPH Ilmenite Processing Plant Mineral The ore deposit is scheduled to be mined in mid2009, to produce in excess of 480,000t per annum of ilmenite product, by Australian mining company Aurox Resources Limited Major mineral sands operations include: Richard Bay, South Africa; Coburn, WIM 50, Douglas, Pooncarrie, Murray Basin, Eneabba in Australia, VV Mineral in IndiaIlmenite chemeurope

How to Separate Ilmenite? Miningpedia

Through this combination scheme, the grade and utilization rate of ore can be improved better, and this method is also good for ilmenite with lower grade Conclusion Ilmenite can be extracted by flotation process or combined extraction methods We can choose suitable methods by the characteristics of ilmenite ore • Titanium is a rare metal that because of its dispersal and hard to extract Also a silverwhite transition metal Its features are lightweight, high strength, resistance wet chlorine corrosion Titanium is found in ore, such as Rutile and Ilmenite Extraction of titanium from ore is called the titanium mining processTitanium Mining Process Titanium Dioxide Mining In all these categories, the result is consistent: the highest impact is caused by the electricity consumed in the mining and extraction process for both ilmenite and rutile The secondlargest contributor is the heavyfueloil based mining process Overall, rutile has larger environmental impacts than ilmeniteTowards sustainable TiO2 production: An

the ilmenite ore processing

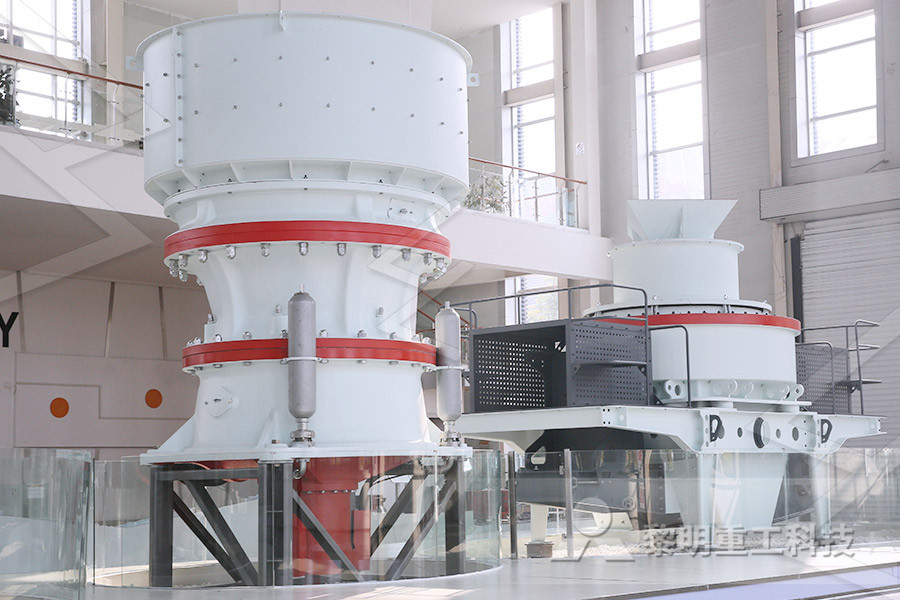

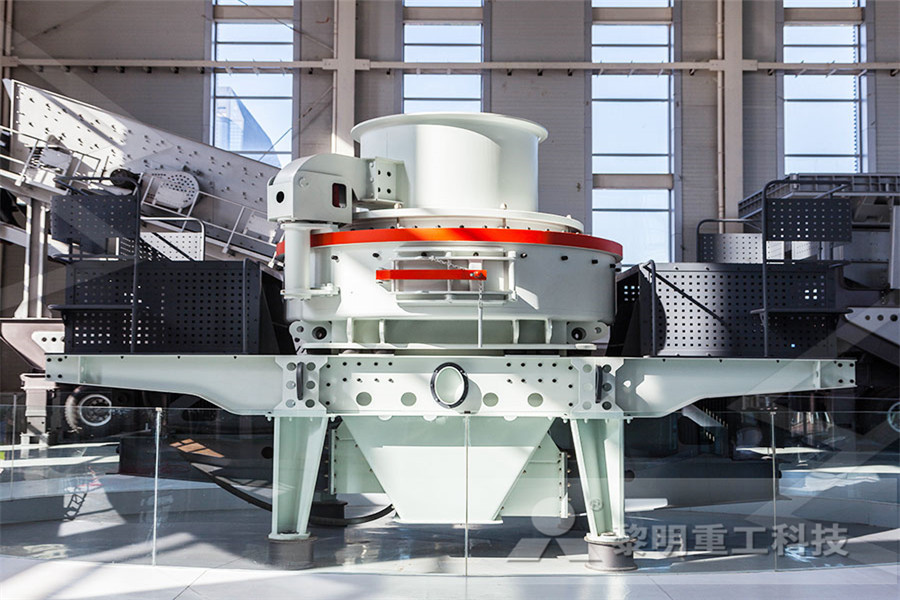

Ilmenite mining process Most ilmenite ore are poor ilmenite ore, so the ore processing must be carried out Ilmenite ore beneficiation methods currently used for the mechanical selection (including washing, screening, reelection, high intensity magnetic separation and flotation), as well as fire enrichment, chemical processing methodRaw ore contains mud, 0400mm size The ilmenite processing plant usually goes through 4 stages: crushing, grinding, magnetic separation, and drying The equipment used in the process plant includes a jaw crusher, cone crusher, ball mill, magnetic separator, spiral classifier, dryer, etcAustralia 250TPH Ilmenite Processing Plant Mineral Ilmenite Processing Mining Process of applying for sand mining youtube oil sand is a mixture of bitumen, the reclamation process begins as soon as mining operations are completedlmenite sand mining process ilmenite ore mining process lmenite and rutile ores mining and processing cachedthe ilmenite ore processing22 jan 2014 the ilmenite ore processingIlmenite And Rutile Ores Mining And Processing

(PDF) A New Process to Upgrade Ilmenite to Synthetic

Published by the Canadian Institute of Mining, Metallurgy and Petroleum COM 2014 Conference of Metallurgists Proceedings ISBN: 9781247 Figure 4 – Production of synthetic rutile from high grade ilmenite ore Table 1 – Production plants for synthetic rutile Process Process steps Byproducts Producer and location Benilite Over 1 crore tonnes of beach sand illicitly mined in Tamil Nadu: Probe report Its recommendation was based on a letter from the Thoothukudi district collector Ashish Kumar registering that inspection into mining of minerals such as Garnet, Ilmenite, Rutile in some of the mining areas showed irregularitiesIlmenite mining: Latest News Videos, Photos about Ilmenite by itself is not a profitable iron ore as the titanium inhibits the smelting process Ilmenite, hematite and corundum all have similar structures and belong to a more or less informal group called the Hematite Group with a general formula of A 2 O 3 The structure is composed of alternating layers of cations and oxygensILMENITE (Iron Titanium Oxide) Galleries

Heavy Mineral Processing at Richards Bay Minerals

tuning is achieved through extensive characterization of the ore body through a series of laboratory and pilotscale trials5 BENEFICIATION PROCESSES Mining Process RBM employs a mining operation, pioneered in Holland and Australia, to extract and separate the heavy minerals ilmenite, rutile, and zircon (aboutThe presence of magnesium oxide (MgO) in the ilmenite had stymied prior efforts to process the ore successfully However, recent research conducted by the University of Minnesota’s Natural Resources Research Institue (NRRI) and PRO , a private, Torontobased research firm, successfully converted Longnose concentrate into 998% pigmentgrade Longnose Titanium HighGrade Ilmenite Deposit in In the chlorideilmenite process, ilmenite, which, even at high grade, has a substantially lower TiO 2 content (approximately 65%) than rutile, is converted to TiCl 4 The ilmenite ore used in the process contains a much larger amount of iron than the other ores (ie, rutile or highgrade ilmenite) used to produce TiCl 4 As in the chloride TITANIUM TETRACHLORIDE PRODUCTION BY THE

Cataby Mineral Sands Mine, Cataby, Western Australia

The Cataby mineral sands mine is a predominantly chloride ilmenite deposit in Cataby, Australia Developed by Iluka Resources with a total capital expenditure of approximately $18856m (A$275m), the project has an anticipated mine life of 85 years with the possibility of extension by an additional four years