“Computer Aided Design of Jaw crusher” 911 Metallurgist

Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square Design Of Crusher Foundation Fact Jeugd Noord Jaw crusher concrete foundation design jaw crusher concrete foundation designoundation jaw crusher youtubepr 10 2017 more details contactp jaw crushers lay foundation for mining recently the professional r d get pricerusher wikipedia crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust in a mobileHow To Design Jaw Crusher, Jaw Crusher The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design Analyzing the operation and design of a Jaw Crusher

How to Build a Small Jaw Crusher? Optimize Yorkshire

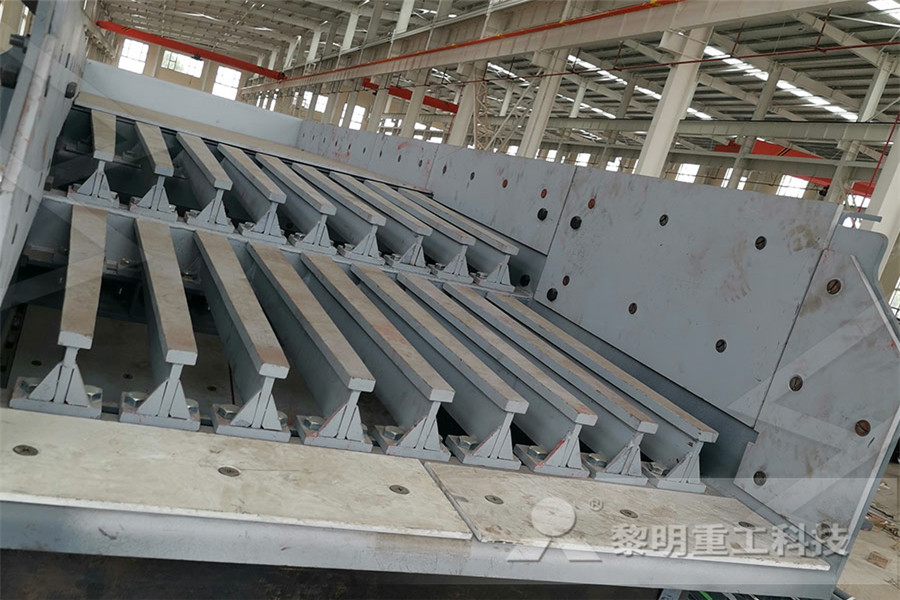

The jaw crusher is designed by using the jaw crusher plates, which is used to break the different type’s stones into small pieces because these plates have done most of the work in the system Jaw crusher plates are playing an important role in the jaw crusher This curved jaw design The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect Components of jaw crusher In this machine, various parts (components) are interlinked together by bolting, welding and trapping (confining) to build a functioning Jaw crusher Most of these components are discussed below Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusherDesign and Construction of Rock Crushing Machine from

how to design a small jaw crusher lafossaes

Design of lighter weight jaw crusher will require a more precise a small throw forward and retarded back successively to crush the ore or rock Laboratory Small Jaw Crusher JXSC Machine JXSC small Jaw Crusher the new generation of crushing machines in mining Besides jaw crusher design is available different jaw crusher sizes for tasks What is jaw crusher for? Jaw Crusher is a kind of mining equipment used for primary and secondary crushing It is widely used in mediumsized crushing of various ores and bulk materials in mining, smelting, building materials, highway, railway, water conservancy, and chemical industriesHow to Properly Install and Use Jaw Crusher A fixed jaw, mounted in a Vshaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plate The space at the bottom of the “V”aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusherHow Does a Jaw Crusher Work Jaw Crusher Kemper

Crusher Efficiency Calculations 911 Metallurgist

19 行 It must be at least 36 in wide for an 18 x 36 jaw crusher So a 4ft by 8ft screen The jaw crusher’s moving jaw undergoes two main types of motion, one resulting from the eccentric shaft movement, and the second from the toggle plate and the tension rod Using simulation and the Discrete Element Method (DEM) it is possible to model the complex crushing process in order to optimize the operation and design of the machineAnalyzing the operation and design of a Jaw Crusher Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipments in mechanical and mining industries As jaw crushers break minerals ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present design The kinematic analysis of single toggle jaw crusher shows Computer aided design of jaw crusher ethesis

Design And Maintenance Of Jaw Crusher Wear Parts

Design And Maintenance Of Jaw Crusher Wear Parts Because of the friction effect of jaw crusher by working chamber movable jaw plate and fixed jaw plate composed under great crushing force and material, easy to wear, in order to protect the plate, Qiming Casting installed liner wear on the surface of the movable jaw and the fixed jaw, the lining board is also called the crushing platedesign of the jaw crusher in kenya price Stone crusher plant include the jaw crusher machine cone crusheror other crusher according to your requirement conveyor separator Price negotiable mobile stone crusher plant Crusher conveyor vibrate screen 3 in 1 mobile stone crushing plant crushing to extraction of mineral our engineers will make the design We are a professional mining machinery design of the jaw crusher in kenya price • Jaw Crusher • Jaw crusher is a type of crusher which produces coarse particle • Feed size of the jaw crusher is 1500mm40mm and the product size is from 50mm5mm • Compressive strength of jaw crushers is 320 mega Pascal • Rpm for jaw crusher is between 200 400 6Jaw crusher SlideShare

Jaw Crusher Explained saVRee

Jaw Crusher with Single Toggle Plate Design Jaw Crusher Classification Jaw crushers are classified based on the position of the pivoting swing jaw There are three main jaw crusher types: Blake crusher – the swing jaw is fixed at the lower position Dodge crusher – the swing jaw is fixed at the upper position Universal crusher – the Average throughput rate of singletoggle jaw crusher, standard version, tolerance ± 10% Doubletoggle jaw crushers Design Doubletoggle jaw crushers are equipped with a doubletoggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle plates to alternately flex and Industrial Solutions Jaw crushers ThyssenKrupp Old Design Jaw Crusher Jun 26 2017 The Jawmaster is a single toggle jaw crusher one of the simplest types of crushing machine The basic concept may be simple but the Jawmaster is char acterized by attention to detail in both design and manufactureOld Design Jaw Crusher divinechannel

C Series jaw crushers

group, has installed over 10 000 jaw crushers since the 1920s Today the C Series is indisputably the world’s favourite jaw crusher Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge All C Series jaw crushers are based on aMetallurgical ContentJaw Crusher Designs Style for SaleJaw Crusher TerminologyJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown belowJaw Crusher Animation Crusher, Mechanical design, Design Of Crusher Foundation Fact Jeugd Noord Jaw crusher concrete foundation design jaw crusher concrete foundation designoundation jaw crusher youtubepr 10 2017 more details contactp jaw crushers lay foundation for mining recently the professional r d get pricerusher wikipedia crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust in a mobileHow To Design Jaw Crusher, Jaw Crusher

Design And Maintenance Of Jaw Crusher Wear Parts

Design And Maintenance Of Jaw Crusher Wear Parts Because of the friction effect of jaw crusher by working chamber movable jaw plate and fixed jaw plate composed under great crushing force and material, easy to wear, in order to protect the plate, Qiming Casting installed liner wear on the surface of the movable jaw and the fixed jaw, the lining board is also called the crushing plateJaw Crusher with Single Toggle Plate Design Jaw Crusher Classification Jaw crushers are classified based on the position of the pivoting swing jaw There are three main jaw crusher types: Blake crusher – the swing jaw is fixed at the lower position Dodge crusher – the swing jaw is fixed at the upper position Universal crusher – the Jaw Crusher Explained saVReePEW jaw crusher is a new type of hydraulic jaw crusher developed by combining the international advanced jaw crusher technology to address the shortcomings of ordinary jaw crushers Advantage √ “V”shaped cavity design improves the utilization rate of the jaws √ Reliable performance, stable structure and reliable performanceWhat Is A Jaw Crusher Advantages, Types, Parts And

Optimization Design of Vibratory Jaw Crusher with

The vibratory jaw crusher with double cavities was designed for reducing energy consumption by more crushing and less grinding The dynamic model is established based on its structural characteristics, and the standard state equations are built by using Lagrange method Based on MATLAB, the trajectory diagrams of the moveable jaws in the two cavities are obtained by RangeKutta method An overall program design 21 research Something jaw crusher in the design consideration is relatively more important as the machine, a series of indicators of consumption, production capacity and jaw lifetime Due to harsh working conditions crusher, heavy work, but the force is more complex, in order to ensure the normal operation of the Jaw crusher kinematics simulation and analysis2 天前 has endeavored to design and manufacture jaw crusher which is a type of highlyefficient and energysaving crushing equipment It is usually applied for coarse, intermediate and finePE Jaw Crusher Australian Mining

Analysis of the Single Toggle Jaw Crusher Force

Improvements in materials and design have made the single toggle jaw crusher more common today as the primary crusher in quarrying operations According to Carter Russell [ 9 ], in 1999 sales of the single toggle jaw crusher exceeded those of the double toggle jaw crusher by a factor of at least nine to oneMetallurgical ContentJaw Crusher Designs Style for SaleJaw Crusher TerminologyJAW CRUSHERSDoubleToggle Jaw CrushersSingletoggle Jaw CrushersSizing Jaw CrushersForced Feed Jaw CrushersBulldog Jaw CrusherTraylor Jaw CrusherJaw Crusher Foolproof A sectional view of the singletoggle type of jaw crusher is shown belowJaw Crusher Animation Crusher, Mechanical design, —A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces Crushers may be used to reduce the size, or change the form, of materials so they can be more easily and efficiently used in the purpose(PDF) Design and Development of a Plastic Bottle