Analysis of explosion risk factor potential on coal

Coal reclaim tunnel A coal reclaim tunnel is facility located underneath the coal stockpile (as illustrated in Fig 1) that serves as a transfer point for coal from the stockpile to other areas Coal from the stockpile will be transferred onto the conveyor belt through the feeder, and then the conveyor brings the coal to the destination, such as a coal barge or vessel 12 Coal reclaim tunnel A coal reclaim tunnel is facility located underneath the coal stockpile (as illustrated in Fig 1) that serves as a transfer point for coal from the stockpile to other areas Coal from the stockpile will be transferred onto the conveyor belt through the feeder, and then the conveyor brings the coal toAnalysis of explosion risk factor potential on coal Coal reclaim tunnelseclaim tunnel for coal mining project case he other tunnel incorporates five different chutes to allow coal to be delivered from the stockpile einforced earth learn moreoal reclaim tunnels crusher, quarry, mining the other tunnel incorporatesfive different chutes to allow coalCoal Reclaim Tunnels Annette Haag Dekorationen

New Reclaim Tunnel at Coal Fired Plant Omaha

New Reclaim Tunnel at Coal Fired Plant Omaha SAME Post Monthly Meeting 10 July 2014 By: Steve Morrissette Zapata Incorporated Omaha, NE Coal Fired Power Plant • Generating capacity: 2,090 megawatts base load • Commercial operations began in 1965 –49 years old • One of the most efficient power plants in US (BTU/kWh) • The product coal tunnel needed to incorporate five different chutes to allow coal to be delivered from the stockpile above through a valve onto the conveyor below The Reinforced Earth Company (RECO) successfully tendered for the design and supply of the two reclaim tunnels with a precast concrete arch design based on the TechSpan® systemNewpac Reclaim Tunnel recoauReclaim Systems CDG understands that coal transfer systems are an integral piece of your plant or facility operations With extensive experience across all aspects of bulk material handling, the engineering team at CDG understands the intricacies associated with chute design and conveyor system design to ensure a superior coal transfer processReclaim Systems Reclaim Tunnel Reclaim Hopper

Reclaim Tunnel Collapse Shirley Consulting Engineers

Reclaim Tunnel Collapse Mount Arthur Coal Mine Shortly after construction in 2002, a concrete arch tunnel at the Mount Arthur coal mine below a reclaim stockpile experienced significant cracking As a consequence, remediation works were designed and A Reclaim Tunnel refers to a buried conduit that encloses a material conveyor The conduit is used to transport aggregate, sand, coal or other minerals from a central stock pile to an off loading location These material stock piles can be as tall as 80’ highUsing Corrugated Steel for Reclaim Tunnel Applications Mining Reclaim Tunnel Conveyors Mining Client hired Hanlon Engineering Architecture, Inc to design a concrete reclaim tunnel to replace an existing horizontal 12′6″ diameter dilapidated corrugated metal tunnel The existing conveyor has a 36″ belt and was very tight in the geometry of the corrugated tunnelMining Reclaim Tunnel Conveyors Hanlon Engineering

Reclaim Tunnel CLOSE CONSULTANTS

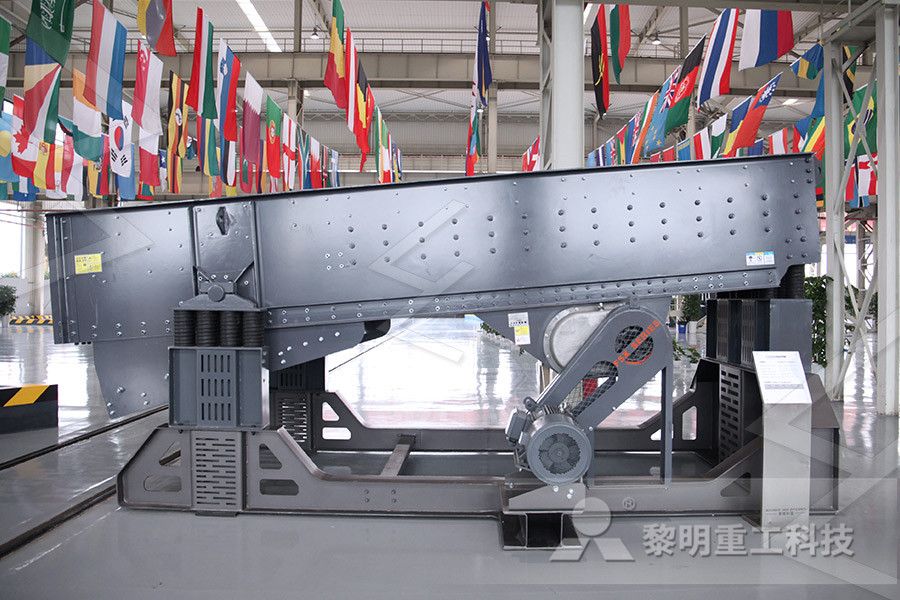

The Reclaim Tunnel is 300m in length with eight discharge point Floor mounted vibrating feeders reclaim and blend coal from the stockpile situated above The stockpile is 20m in height At the dead end of the tunnel and running perpendicular to it is a small escape tunnel Abstract A failure along any part of the coal supply chain can result in major delays and costs to coal companies and associated distributors This paper discusses the geotechnical / geophysical methods used to investigate a damaged 40 m length of steel multiplate arch reclaim tunnel and also briefly discusses the remedial measures used to reinstate the tunnelInvestigation of reclaim tunnel, coal mine – Australian Reclaim Systems CDG understands that coal transfer systems are an integral piece of your plant or facility operations With extensive experience across all aspects of bulk material handling, the engineering team at CDG understands the intricacies associated with chute design and conveyor system design to ensure a superior coal transfer process In times past, the focus of coal handling Reclaim Systems Reclaim Tunnel Reclaim Hopper

Power Plant Reclaim Tunnel Safety Products

Coal Mills/Pulverizers Products Compressor Turbine Area Products Select Product Category Fire Protection Reclaim Tunnel Products Select Mangoola Coal Stockpile Reclaim Tunnel, Muswellbrook, NSW Project featuring the Atlantic Civil Products MSE System Call Us Now (02) 9899 2111 General Information Mangoola Coal is an open cut coal operation in the Wybong area, 20 kilometres west of Muswellbrook and approximately 10 kilometres north of the township of Denman, NSW Mangoola Mangoola Coal Stockpile Reclaim Tunnel, Shortly after construction in 2002, a concrete arch tunnel at the Mount Arthur coal mine below a reclaim stockpile experienced significant cracking As a consequence, remediation works were designed and supervised by a large multidisciplinary engineering firm Four years later, the tunnel again partially collapsed, and a different large multidisciplinary engineering firm wasReclaim Tunnel Collapse Shirley Consulting Engineers

Train Unloading Station and Reclaim Tunnel CLOSE

The conveyor in the foreground is the reclaim conveyor which is fed by eight vibrating feeders The feeders draw coal from eight hoppers which are situated below the train unloading station Ulan Coal: Eraring Power Station ventilation fans for coal reclaim tunnel – Marks of Books ventilation fans for coal reclaim tunnel [Full Version] 6061 dl’s @ 3623 KB/s Microsoft Word – Idaho State Content Standards with Limits, 3rd »More detailedventilation standards coal reclaim tunnel united states Reclaim TunnelsA Reclaim Tunnel refers to a buried conduit that encloses a material conveyor The conduit is used to transport aggregate, sand, coal or other minerals from a central stock pile to an off loading location These material stock piles can be as tall as 80’ high Reclaim Tunnels will normally have hopper openings to allow flow of theUsing Corrugated Steel for Reclaim Tunnel

Glencore Coal Conveyor Tunnel Fire Detection

The raw coal, product coal, and train loading conveyor and reclaim tunnel fire detection system was put into operation this month allowing Bulga Coal to fully protect 10 conveyors covering a total of 5 km in length The linear heat detection fibre optic system also provides early warning of abnormal heat buildup around equipment The Reclaim Tunnel is 300m in length with eight discharge point Floor mounted vibrating feeders reclaim and blend coal from the stockpile situated above The stockpile is 20m in height At the dead end of the tunnel and running perpendicular to it is a small escape tunnel Reclaim Tunnel CLOSE CONSULTANTSAbstract A failure along any part of the coal supply chain can result in major delays and costs to coal companies and associated distributors This paper discusses the geotechnical / geophysical methods used to investigate a damaged 40 m length of steel multiplate arch reclaim tunnel and also briefly discusses the remedial measures used to reinstate the tunnelInvestigation of reclaim tunnel, coal mine – Australian

Reclaim Tunnel Hunter Valley CLOSE CONSULTANTS

The Reclaim Tunnel is nominally 300m in length with eight discharge points Floor mounted vibrating feeders reclaim and blend coal from a 20m high stockpile situated above At the dead end of the tunnel and perpendicular to it, runs a small escape tunnel formed from precast culverts The conveyor in the foreground is the reclaim conveyor which is fed by eight vibrating feeders The feeders draw coal from eight hoppers which are situated below the train unloading station Ulan Coal: Eraring Power StationTrain Unloading Station and Reclaim Tunnel CLOSE Coal Mills/Pulverizers Products Compressor Turbine Area Products Select Product Category Fire Protection Reclaim Tunnel Products Select Power Plant Reclaim Tunnel Safety Products

Coal Reclaim Tunnels mayukhportfolioco

Coal Reclaim Tunnel Freeze Up Problems FR Belt in Coal Reclaim Tunnels bulkonline Forums Thursday, June 06 14 / php?3714FRBeltinCoalReclaimTunnels I have read the thread started by Kayem re FR Reclaim TunnelsA Reclaim Tunnel refers to a buried conduit that encloses a material conveyor The conduit is used to transport aggregate, sand, coal or other minerals from a central stock pile to an off loading location These material stock piles can be as tall as 80’ high Reclaim Tunnels will normally have hopper openings to allow flow of theUsing Corrugated Steel for Reclaim Tunnel The raw coal, product coal, and train loading conveyor and reclaim tunnel fire detection system was put into operation this month allowing Bulga Coal to fully protect 10 conveyors covering a total of 5 km in length The linear heat detection fibre optic system also provides early warning of abnormal heat buildup around equipmentGlencore Coal Conveyor Tunnel Fire Detection

Glencore Coal adopts APAPL’s Conveyor Tunnel Fire

Advanced Photonics Australia’s Director Ubaldo Torre is proud to announce the signing of a contract with Glencore Coal The contract will provide a fully redundant fibre optic cable DTS based fire detection system for the Bulga Coal Handling Plant for the surface and reclaim tunnel conveyors The system will provide area coverage from the run []The CHPP comprised a raw coal stockpile reclaim system incorporating three coal feeders onto a reclaim conveyor located in a tunnel, a twostage reduction crushing station, a plant feed system, and dry disposal reject handling systemDonkin Coal Project, Nova Scotia Mining Technology